Know Why Thin Magnetic Sheeting is the Smart Choice for Businesses

Magnetic sheeting is a flexible material that can be magnetized on one side and often has an adhesive or printable surface on the other. It

When selecting a Pressure Sensitive Adhesive (PSA), specific characteristics of the materials, environmental factors, application conditions, cost concerns, and the required bonding performance all need to be considered.

Substrates or surfaces vary widely though you should pay attention to a few key attributes regarding adhesive tapes:

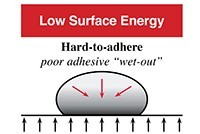

Surface Energy – The strength of attraction between two surfaces is determined by the surface energy of the material. The higher the surface energy, the greater the molecular bond. The lower the surface energy, the weaker the attractive forces.

High Surface Energy (HSE) materials allow the adhesive to flow or “wet out” for a stronger bond. For example, when it rains on an unwaxed car, the water spreads out creating puddles. In this case, the car’s surface is displaying High Surface Energy (HSE). However, a waxed car will cause water to bead up because the car’s surface is displaying Low Surface Energy (LSE) and therefore resist adhesive wet out and makes bonding more challenging.

Rubber based and modified acrylic adhesives typically offer better adhesion to LSE substrates, as they are softer and flow better.

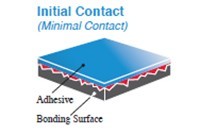

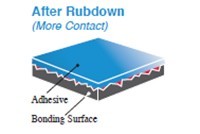

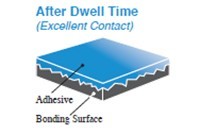

Adhesive Surface Contact – Applying firm pressure to the bond increases adhesive flow and contact or a

more secure bond. Time and temperature will typically further increase the contact and adhesive values.

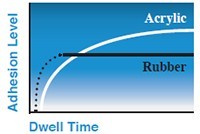

Dwell Time gives the adhesive time to flow, effectively covering your substrates. Rubber adhesives set up more quickly where Acrylic Adhesives typically require 72 hours before testing for the ultimate adhesion strength.

Surface Contamination – Grease, moisture, oil, mold, chemicals, and dust are just a few contaminates that affect tackiness and can result in a poor permanent bond of adhesive tapes. Always clean and dry your substrates before applying a pressure sensitive adhesive.

Chemical/Solvent/Plasticizers – Some substrates can cause adhesive swelling, softening and even dissolve your adhesive. Many acrylic adhesives have varying resistance and can withstand these effects for extended periods of time.

Temperature – Apply adhesives at room temperature. Low temperatures can reduce tack and make the adhesive firm and brittle. High temperatures can reduce cohesive strength, shear strength and cause softening. Know the temperature range of your application to choose the proper adhesive.

UV Light – Exposure may cause discoloration, adhesive brittleness and chemical degradation of adhesive tapes. If UV light is a factor, select an adhesive that is UV resistant.

Selecting the right adhesive tape for your application is key for the success of your project. Our team can help you walk through some key considerations when determining which adhesive tape is best suited for you.

Simply complete and submit the online form below and we’ll review your specs and contact you with any questions.

Magnetic sheeting is a flexible material that can be magnetized on one side and often has an adhesive or printable surface on the other. It

Magnets come in various shapes and sizes, each designed for specific uses. Understanding the different shapes of magnets, their properties, and their applications can help

Magnets are a fascinating part of our everyday lives, from the magnets on our fridge doors to the powerful magnets used in advanced technology. There

Our magnet experts will help you get exactly what you need – custom or stock – in record time with great quality at a very competitive price.

Ⓒ 2024 - All Rights Are Reserved