Whether you’re a DIY enthusiast, a professional in construction, or just curious about magnets, this guide will provide you with all the information you need to understand and utilize countersunk magnets effectively.

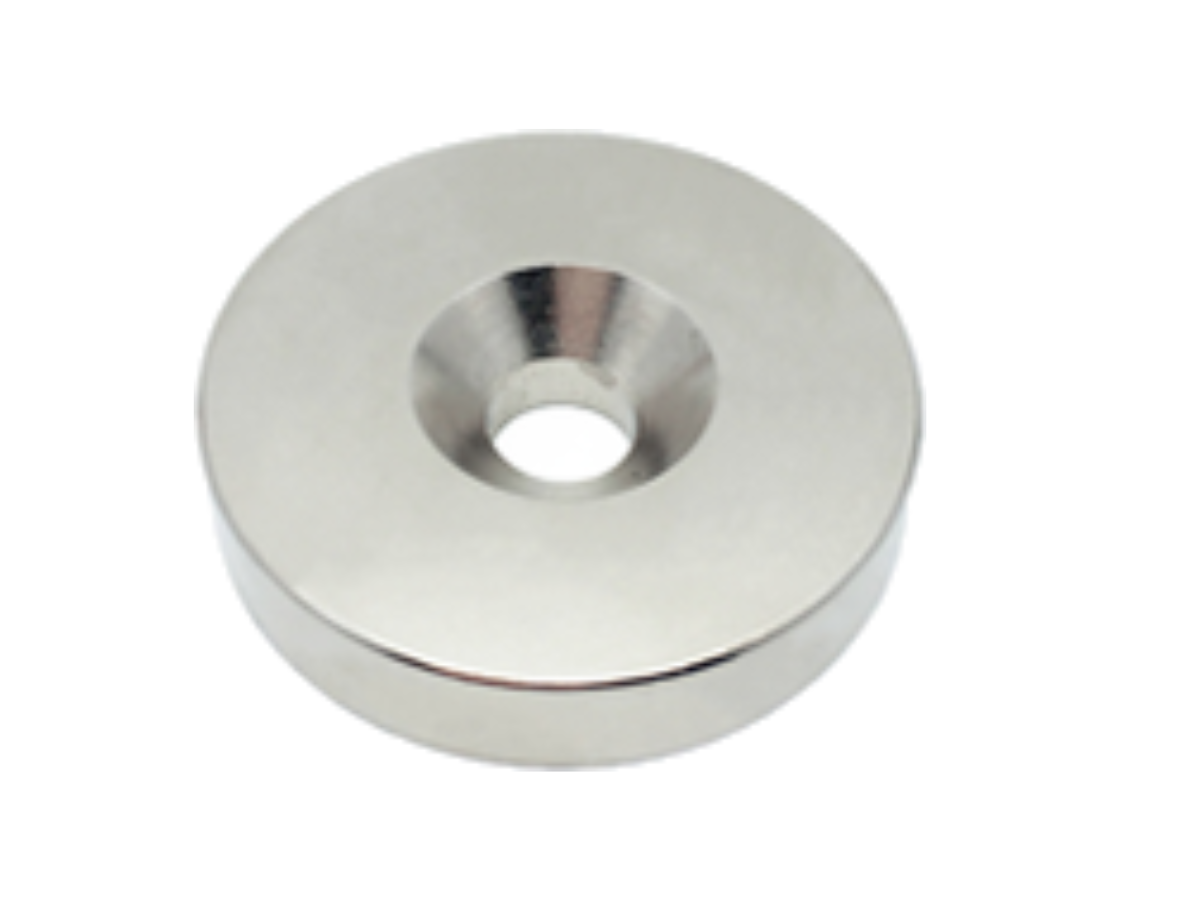

Countersunk magnets are a type of magnet designed that has a ring-like shape with a hole in the middle, allowing them to be easily attached to surfaces using screws. The countersunk hole makes the magnet sit flush with the surface, providing a sleek and secure fit. These magnets are usually made from neodymium, which is one of the strongest types of permanent magnets available.

Neodymium countersunk magnets are incredibly powerful, offering a high magnetic pull relative to their size. This makes them suitable for various applications where a stronghold is necessary.

The countersunk hole allows for easy installation with standard screws. The conical shape ensures that the screw head sits flush with the magnet’s surface, creating a neat and professional look.

These magnets are versatile and can be used in a wide range of applications, from industrial uses to home projects. They are perfect for attaching objects to metal surfaces, creating magnetic closures, or even building custom magnetic tools.

Neodymium magnets are known for their durability. They maintain their magnetic strength over time and are resistant to demagnetization and corrosion, especially when coated with protective layers such as nickel or epoxy.

One of the most common uses of countersunk magnets is in cabinet and door closures. By embedding a magnet into the door and a metal plate or another magnet into the frame, you can create a strong, invisible closure mechanism that keeps doors securely shut without the need for traditional latches.

Countersunk magnets are ideal for creating custom tools and knife holders. By mounting these magnets onto a wall or inside a cabinet, you can easily organize your tools or knives, keeping them accessible and securely in place.

In retail environments, countersunk magnets are often used to mount signs and displays. They allow for quick and easy installation and removal, making it simple to change out signage as needed without damaging the walls or fixtures.

Countersunk magnets can be used in furniture assembly to create removable panels or components. This can be particularly useful in modular furniture designs, where components need to be easily detachable for transport or reconfiguration.

In automotive and marine industries, countersunk magnets are used to hold panels, covers, and other components in place. Their stronghold and resistance to environmental factors make them ideal for these demanding applications.

When selecting a countersunk magnet, there are several factors to consider to ensure you choose the right one for your needs.

Countersunk magnets come in various sizes and shapes. The size of the magnet will determine its holding power, so it’s important to choose a size that matches the requirements of your application. Larger magnets will generally provide a stronger hold.

Neodymium is the most common material used for countersunk magnets due to its superior strength. However, it’s also important to consider the coating of the magnet. Common coatings include nickel, zinc, and epoxy, each offering different levels of protection against corrosion and wear.

The pull force of a magnet is a measure of how much weight it can hold. When selecting a magnet, consider the weight of the objects you plan to attach and choose a magnet with a suitable pull force. Manufacturers usually provide this information, so be sure to check the specifications.

Neodymium magnets can lose their magnetism at high temperatures. If your application involves high temperatures, look for magnets that are rated for higher temperature resistance to ensure they maintain their strength under these conditions.

Installing countersunk magnets is straightforward, but following a few key steps will ensure a secure and effective installation.

You will need:

Use a measuring tape or ruler to determine the exact placement of the magnets. Mark the spots with a pencil or marker to ensure accurate alignment.

If you are attaching the magnets to a material that requires pre-drilled holes (such as wood), use a drill to create pilot holes. This will make it easier to screw in the magnets and prevent the material from splitting.

Align the countersunk hole of the magnet with the marked spot and insert the screw through the hole. Use a screwdriver or drill to secure the screw, ensuring that the head sits flush with the magnet’s surface. Repeat this process for each magnet.

Once all magnets are installed, test their hold by attaching the corresponding metal or magnetic components. Make sure everything is aligned correctly and that the magnets provide the desired level of hold.

Ensure that the screws you use are compatible with the countersunk holes and the material you are attaching them to. The wrong screws can weaken the hold or damage the magnet.

When securing the magnets with screws, avoid over-tightening. This can cause the magnet to crack or the material to become damaged.

If you’re using the magnets in environments where they might be exposed to moisture or chemicals, choose magnets with a protective coating to prevent corrosion.

Neodymium magnets are powerful and can pinch fingers or skin if not handled carefully. Keep them away from electronic devices, as they can affect or damage sensitive components.

Countersunk magnets are a versatile and powerful tool that can simplify many tasks, from home projects to industrial applications. Their strong magnetic force, easy installation, and sleek design make them an excellent choice for various uses.

Remember to consider factors like size, material, pull force, and temperature resistance when selecting your magnets, and follow best practices for installation to ensure a secure and long-lasting hold.

Magnetic sheeting is a flexible material that can be magnetized on one side and often has an adhesive or printable surface on the other. It

Magnets come in various shapes and sizes, each designed for specific uses. Understanding the different shapes of magnets, their properties, and their applications can help

Magnets are a fascinating part of our everyday lives, from the magnets on our fridge doors to the powerful magnets used in advanced technology. There

Our magnet experts will help you get exactly what you need – custom or stock – in record time with great quality at a very competitive price.

Ⓒ 2024 - All Rights Are Reserved