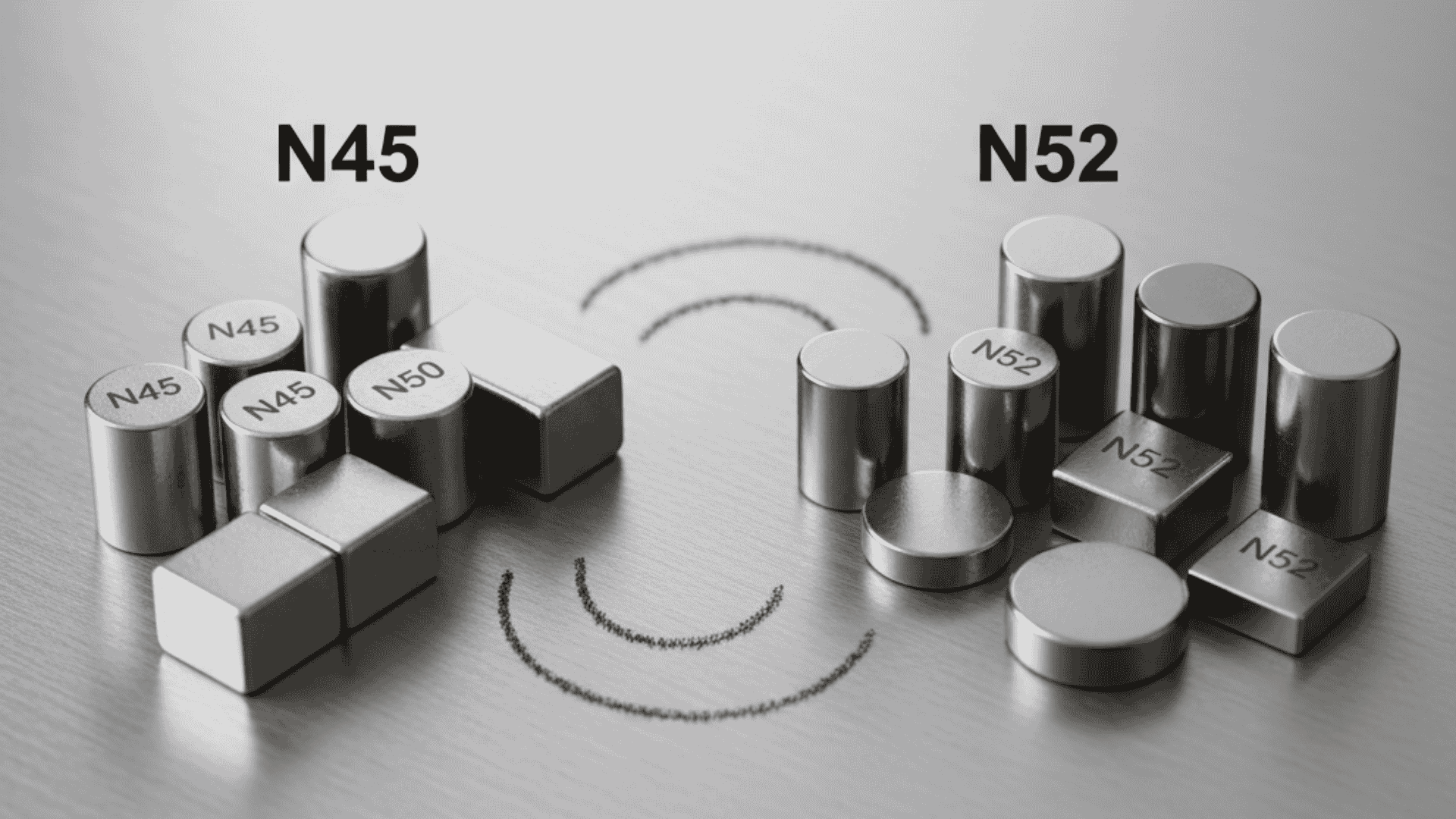

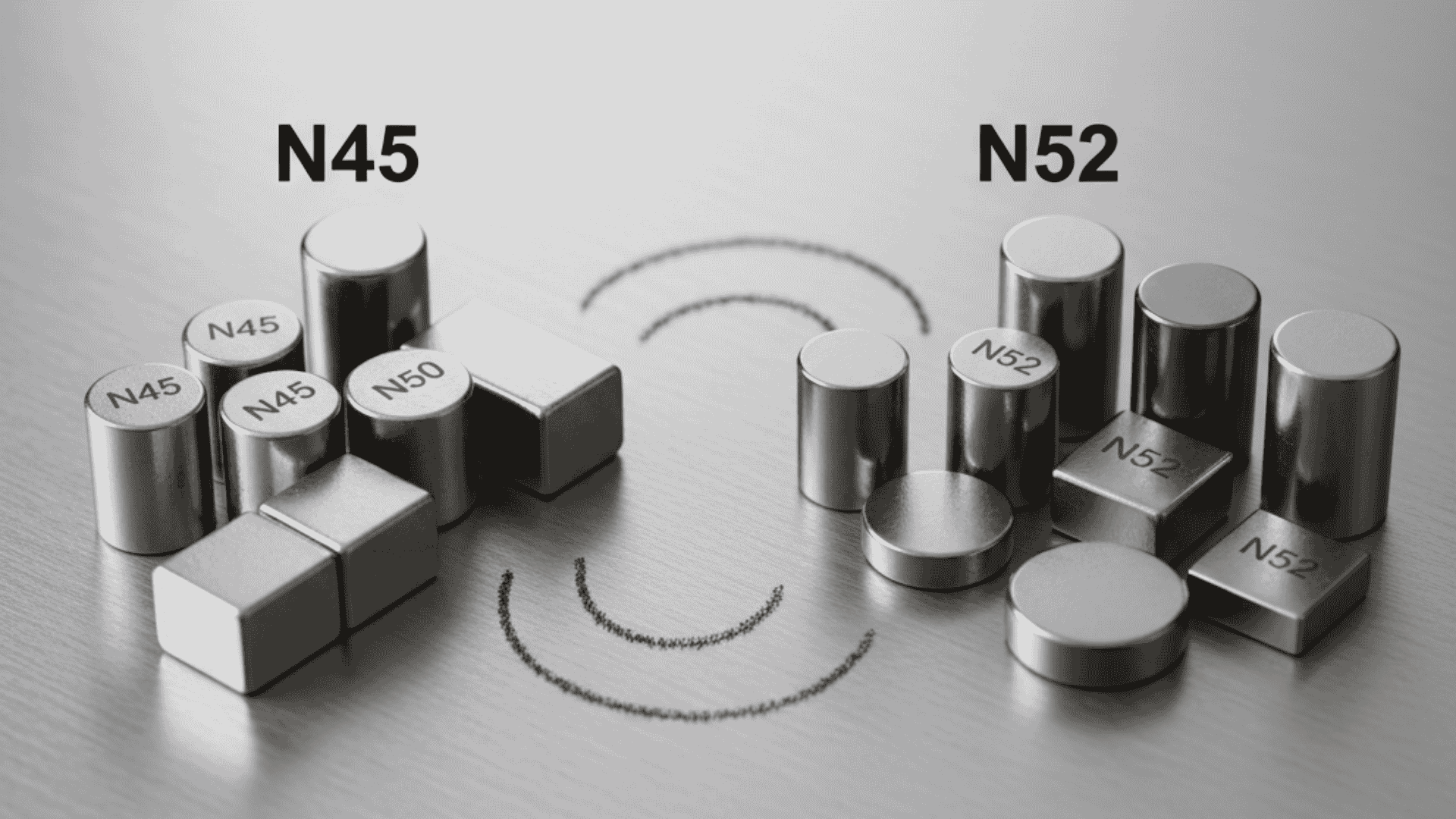

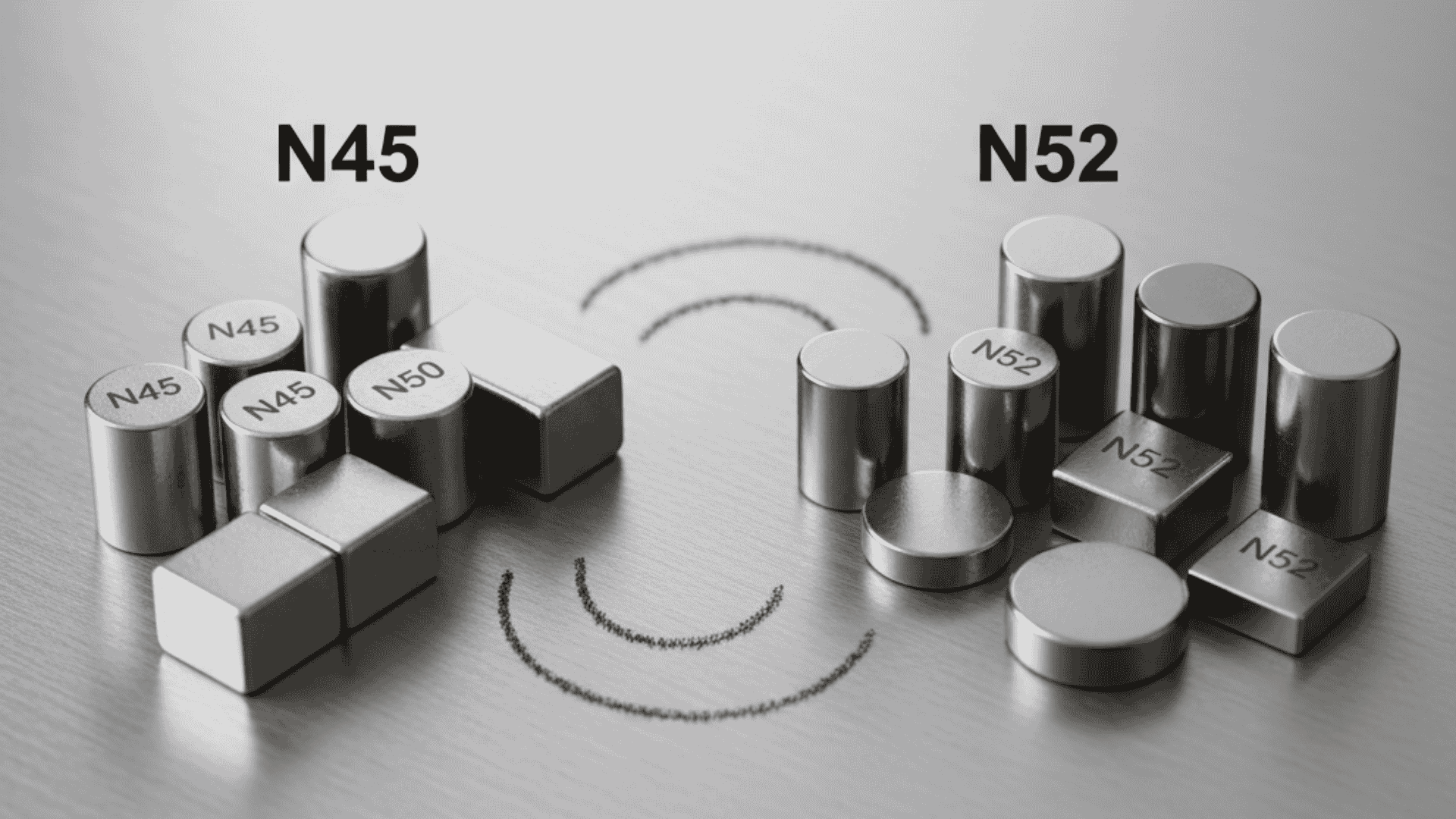

Selecting the right magnet grade is a critical decision for engineers, manufacturers, and product designers. Among the most commonly compared options are N45 and N52 neodymium magnets. While both belong to the family of high-performance rare earth magnets, subtle differences in strength, performance, and suitability can significantly impact real-world applications.

This guide is designed to help buyers understand how these two magnet grades compare, where each performs best, and how to make the right choice based on technical and operational needs.

Neodymium magnets are classified by grades that indicate their maximum energy product, a measurement related to magnetic strength. These grades are part of standardized neodymium magnet grades, allowing engineers to compare performance reliably across applications.

Higher grade numbers generally indicate stronger magnetic force. However, strength alone should never be the only factor in magnet selection. Temperature resistance, size constraints, cost considerations, and environmental conditions all play important roles in determining the best fit. A practical overview of neodymium magnets, explaining magnetic properties, performance benefits, manufacturing considerations, and how these powerful rare earth magnets enhance functionality in engineering, industrial, and precision-component applications.

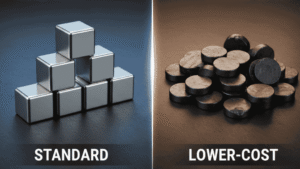

An N45 magnet offers a strong balance between performance, stability, and cost-effectiveness. It is widely used in industrial, commercial, and engineering applications where reliable magnetic force is required without pushing design limits.

When discussing N45 magnet strength, it is important to recognize that this grade delivers excellent holding power in compact sizes. It is often chosen for applications that demand consistent performance while operating within moderate temperature ranges.

Typical uses include:

N45 magnets are popular because they provide dependable results without the premium cost associated with higher grades.

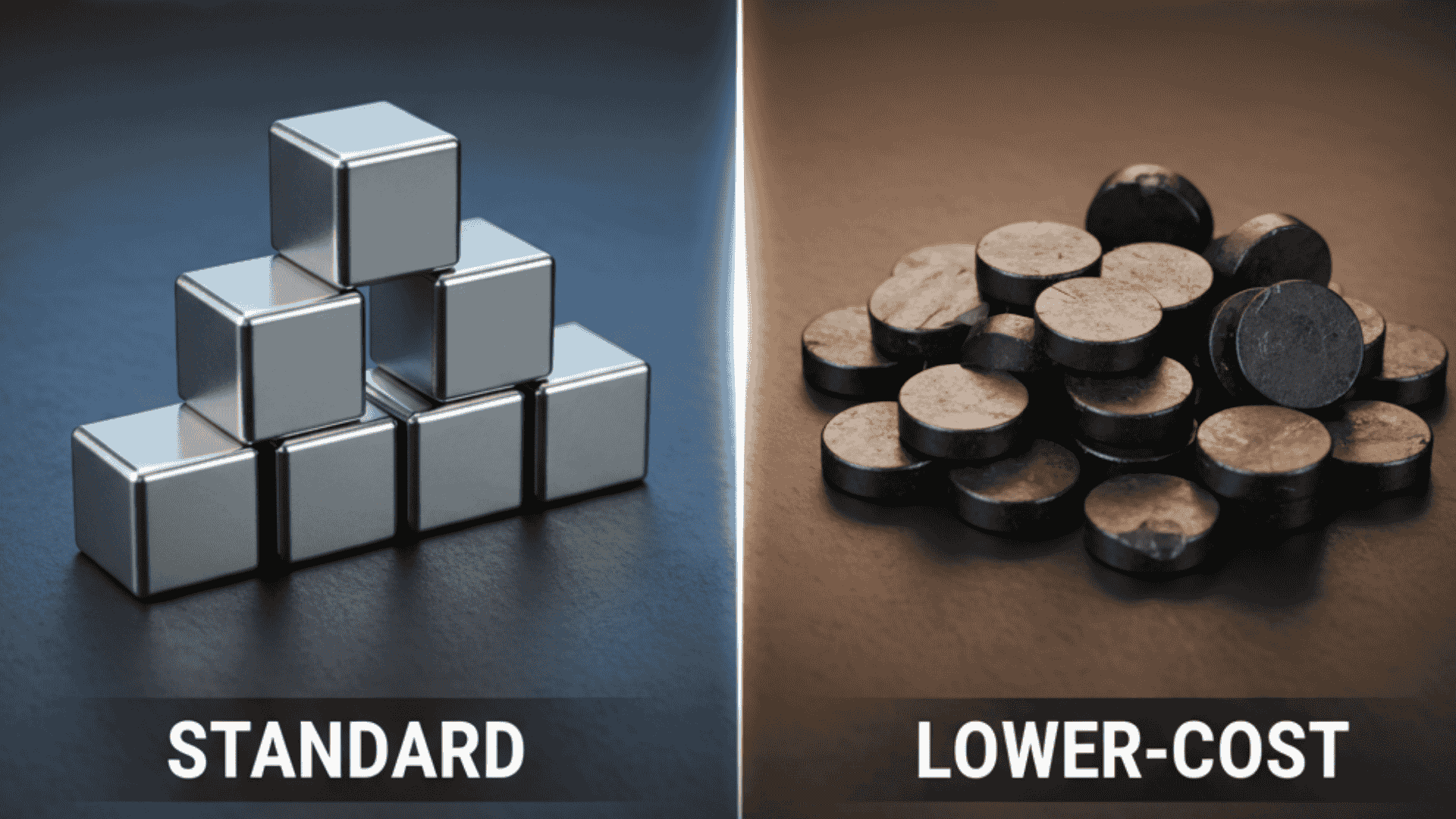

N52 magnets represent the highest standard strength available in commercially produced neodymium magnets. They are engineered for applications that require maximum magnetic output in the smallest possible form factor.

The defining characteristic of N52 magnet strength is its ability to generate exceptionally high magnetic force compared to other grades. This makes N52 magnets ideal for designs where space is extremely limited but performance requirements are high.

Common applications include:

Because of their superior performance, N52 magnets are often selected for cutting-edge and high-demand engineering solutions.

One of the most frequent questions buyers ask is how these grades differ in real-world performance. In the debate of N45 vs N52 magnet, the primary distinction lies in magnetic force output per unit volume.

N52 magnets can produce noticeably higher pull force than N45 magnets of the same size. This means designers may reduce magnet size while maintaining required performance, which can be a major advantage in compact assemblies.

However, the difference between N45 magnet vs N52 magnet strength is not always necessary or beneficial. In many applications, the added force of N52 may exceed requirements, providing little practical advantage while increasing cost and sensitivity. Comprehensive buyer’s guide comparing N52 vs N35 neodymium magnets, exploring strength, performance differences, and ideal application considerations for engineers

While magnetic force is important, it is only one piece of the puzzle. Understanding the difference between N45 and N52 magnets also requires examining factors such as thermal stability, mechanical behavior, and environmental exposure.

Both N45 and N52 magnets:

In some cases, higher-strength magnets may be more sensitive to temperature or mechanical stress. Engineers must ensure that the magnet grade aligns with operating conditions to avoid performance degradation.

Cost is a practical consideration for most buyers. N52 magnets typically command a higher price due to their increased energy density and tighter manufacturing tolerances. N45 magnets, on the other hand, often provide a more economical solution with minimal compromise in performance for many applications.

When evaluating N45 vs N52 neodymium magnets, it is important to consider total system cost rather than magnet price alone. In some designs, a stronger magnet may reduce the number of components or simplify assembly, offsetting higher material costs.

Choosing the correct magnet grade should always be driven by application requirements. Below are general guidelines to help buyers decide:

Choose N45 when:

Choose N52 when:

Understanding these trade-offs helps buyers select the most effective solution without overengineering.

In many cases, magnet grade selection is not a standalone decision. Engineers often evaluate magnet geometry, orientation, coating, and assembly design alongside grade selection to achieve optimal performance.

Working with experienced magnet specialists allows buyers to validate assumptions, test prototypes, and ensure the selected grade performs as expected. Proper analysis can reveal that an N45 magnet may be sufficient, or that an N52 magnet is essential, for long-term success.

Durability and consistency are essential for any magnetic component. Both N45 and N52 magnets are designed to maintain magnetic properties over time when properly specified and protected.

Environmental factors such as humidity, vibration, and thermal cycling should be considered early in the design process. Selecting the right grade reduces the risk of demagnetization, mechanical failure, or unexpected performance loss over the product’s lifecycle.

There is no universal “better” option when comparing N45 and N52 magnets. The correct choice depends on balancing performance needs, physical constraints, budget, and operating conditions.

Buyers who understand the practical implications of magnet grades can make informed decisions that enhance product reliability and efficiency. Whether prioritizing cost-effective performance or pushing the limits of compact design, careful evaluation ensures the magnet selected delivers value beyond its magnetic force.

Choosing between N45 and N52 magnets is ultimately about aligning magnet capabilities with application demands. By understanding grade characteristics, strength differences, and design considerations, buyers can confidently select the magnet that best supports their engineering goals.

With thoughtful planning and expert guidance, the right magnet grade becomes a powerful contributor to innovation, performance, and long-term success.

Selecting the right magnet grade is a critical decision for engineers, manufacturers, and product designers. Among the most commonly compared options are N45 and N52

Modern engineering is defined by efficiency, precision, and innovation. As industries push for compact designs, higher performance, and smarter systems, magnetic solutions have become essential

Neodymium magnets have become essential components across industries, from manufacturing and electronics to retail displays and warehouse systems. Known for their exceptional strength and versatility,