Magnets play an essential role in our daily lives. From the devices we use to the machines that power our industries, magnets are everywhere. But not all magnets are made the same way.

Two common varieties are sintered magnets and bonded magnets. If you’ve heard these terms before and wondered what sets them apart, this simple guide will explain the difference between sintered and bonded magnets in a way that’s easy to understand.

By the end, you’ll know all about sintered vs bonded rare earth magnets, their unique features, and the best choice for your needs!

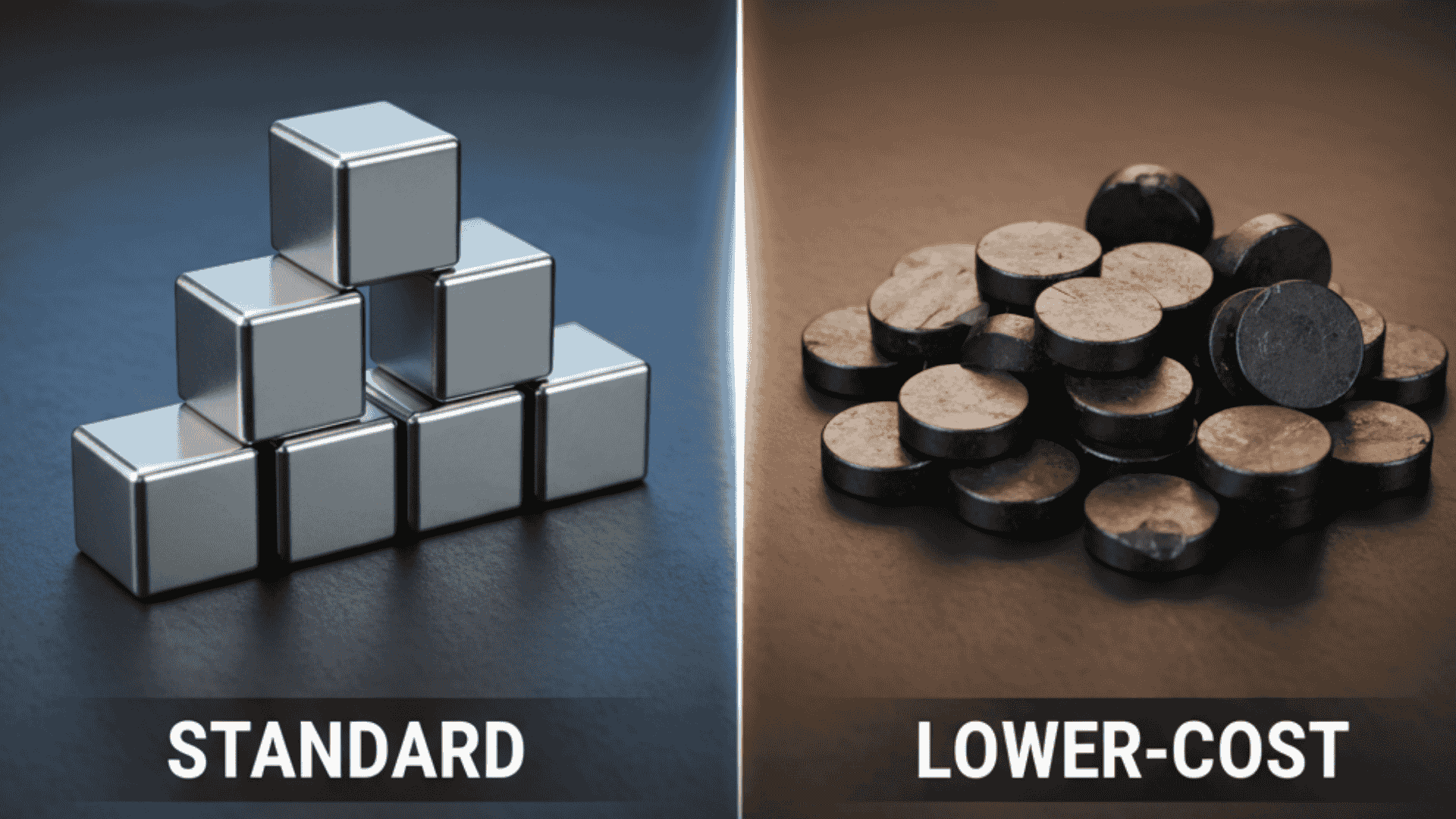

Bonded magnets are created by mixing tiny magnetic powders with a binding agent like resin or polymer. This mixture is poured into molds to create shapes, which are then hardened to form a solid magnet. Think of it like making a cake batter, pouring it into different molds, and letting it harden into the desired shape.

Bonded magnets are ideal for applications requiring small yet powerful magnets. Some common uses include:

Pros:

Cons:

If you need a lightweight, versatile, and low-cost magnet, bonded magnets are a solid choice.

Sintered magnets are made differently. Tiny magnetic particles are compressed under high pressure until they form a dense block. This compact block is then heated at high temperatures—a process known as “sintering”—until the particles bond together. Imagine squeezing sand into a solid clump and then baking it so it holds its shape permanently.

Sintered magnets are designed for heavy-duty tasks where strength is the most important factor. Typical applications include:

Pros:

Cons:

If your project demands top magnetic power and durability, sintered magnets are the way to go.

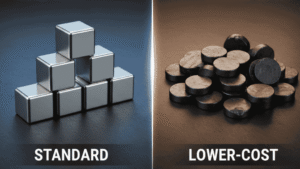

Both bonded and sintered rare earth magnets are made from similar materials but differ greatly in how they perform and are used. Here’s a quick comparison of bonded vs sintered rare earth magnets:

| Aspect | Bonded Magnets | Sintered Magnets |

| Magnetic Strength | Weaker due to added binding material. | Stronger because of its compact, dense structure. |

| Production Method | Molded from a mix of magnetic powder and resin. | Pressed and heated at high temps for densification. |

| Cost | More affordable and easier to produce. | More expensive due to intensive manufacturing. |

| Flexibility of Shapes | Can be molded into any complex form. | Limited to basic shapes, often needs machining. |

| Heat Resistance | Not suitable for high-temperature tasks. | Performs better in extreme heat conditions. |

| Corrosion Resistance | Naturally resistant, no coating needed. | Requires a protective coating like nickel or epoxy. |

By comparing these traits, it’s easier to see how rare earth sintered vs bonded magnets are suited to different needs.

When deciding whether to use bonded or sintered magnets, it helps to think about your project’s priorities and environment.

You need magnets with unique, detailed shapes or if affordability and corrosion resistance matter most. These are perfect for small, everyday devices like printers, appliances, and sensors.

You need serious magnetic strength or are working on large-scale machinery, medical equipment, or aerospace projects. Though more expensive, their power and performance justify the cost of demanding applications.

Understanding the difference between sintered and bonded magnets is essential when picking the right type for your project. Whether it’s the flexibility and cost-effectiveness of bonded magnets or the strength and durability of sintered magnets, both options bring unique benefits. Selecting the right one depends on your project needs, environment, and budget.

Hopefully, this guide to bonded vs sintered rare earth magnets has cleared up the key differences. Now, the next time you hear about sintered and bonded rare earth magnets, you’ll know exactly what they’re all about and how they work! Whatever your application, there’s a magnet out there tailored perfectly for you.

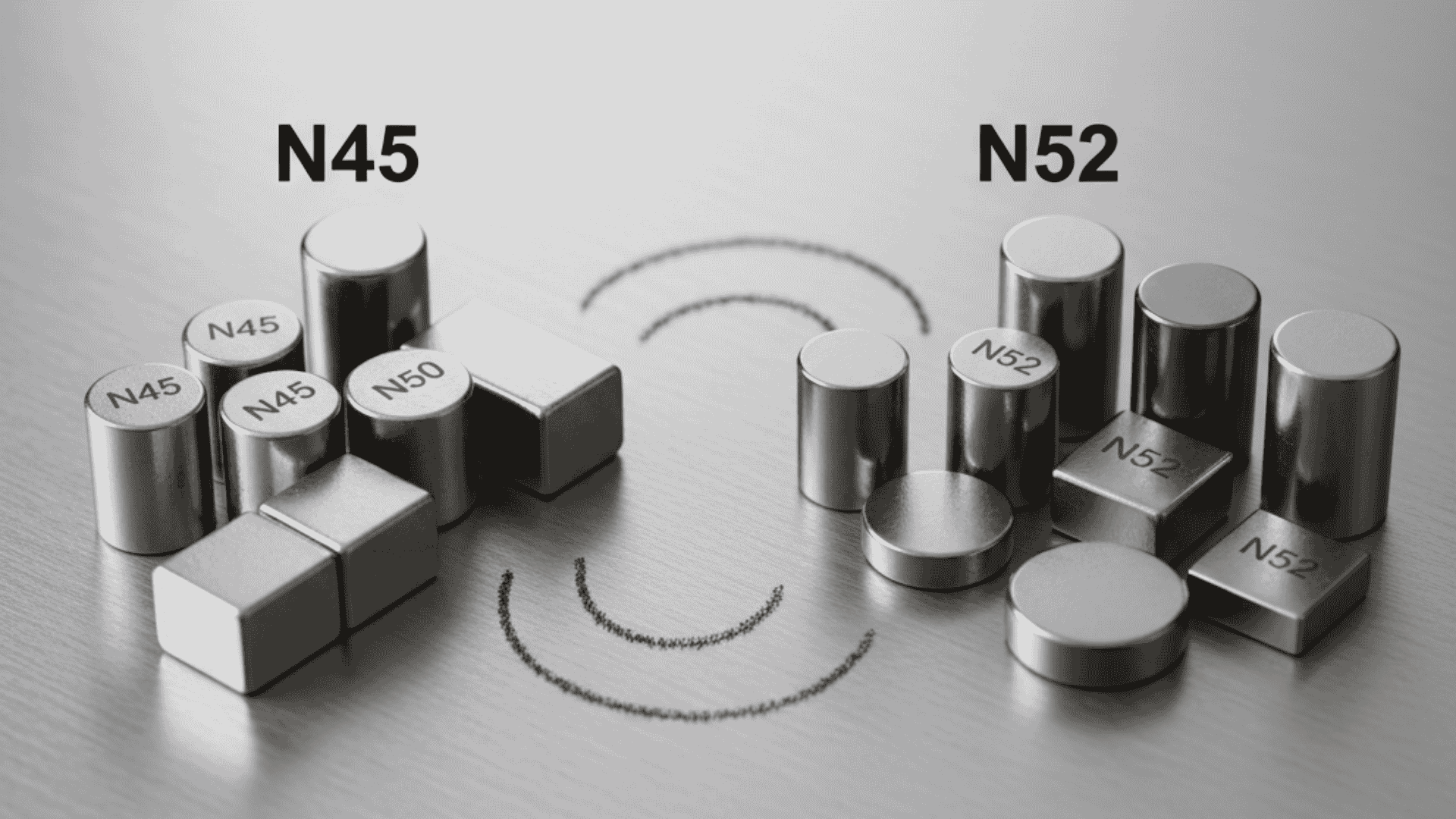

Selecting the right magnet grade is a critical decision for engineers, manufacturers, and product designers. Among the most commonly compared options are N45 and N52

Modern engineering is defined by efficiency, precision, and innovation. As industries push for compact designs, higher performance, and smarter systems, magnetic solutions have become essential

Neodymium magnets have become essential components across industries, from manufacturing and electronics to retail displays and warehouse systems. Known for their exceptional strength and versatility,