Magnets are all around us, quietly doing their job in countless products and industries. One of the most powerful types is called neodymium magnets, which belong to a category known as rare earth magnets. These super-strong magnets are used in everything from electric motors to medical devices, and they come in different “grades.”

If you’re running a business that uses these magnets, understanding neodymium magnet grades is key to choosing the right one for your needs. Here’s how…

Magnet grades tell you how strong a magnet is. Think of it like a rating system for magnets. If you hear about a magnet with a grade of N35 or N52, that number gives you an idea of the magnet’s strength. The higher the number after the “N,” the more powerful the magnet.

For example, an N52 neodymium magnet is one of the strongest you can get, while an N35 is a bit weaker but still very strong compared to other types of magnets. But before you think “higher grade = better magnet,” it’s important to understand that the best grade depends on how you’re planning to use the magnet.

Magnet grades are based on something called “maximum energy product” (measured in units called megagauss-oersteds, or MGOe). That might sound tricky, but it just means how much energy the magnet can store.

Here’s a quick comparison of common neodymium magnet grades to help you out:

For businesses, understanding N35 to N52 magnet grades makes it easier to decide which magnet is right for specific tasks.

Neodymium magnets aren’t a one-size-fits-all product. Different magnet grades exist because each type of magnet is designed for specific temperatures, strengths, and environments. For example, some magnet grades are designed to keep their strength at high temperatures, while others lose their power when it gets too hot.

If your application involves high heat, you might need a special magnet grade that can handle it (these are often marked with letters like “H” or “SH” for “high temperature”). Rare earth magnet grades like these are crucial in industries like robotics or automotive manufacturing.

Businesses often need to do a magnet-grade comparison to figure out which option is best for their products. Here’s a simple breakdown to help you understand how some of the most common grades compare:

Choosing the right magnet grade for industrial use can save your business money while ensuring your products work as intended.

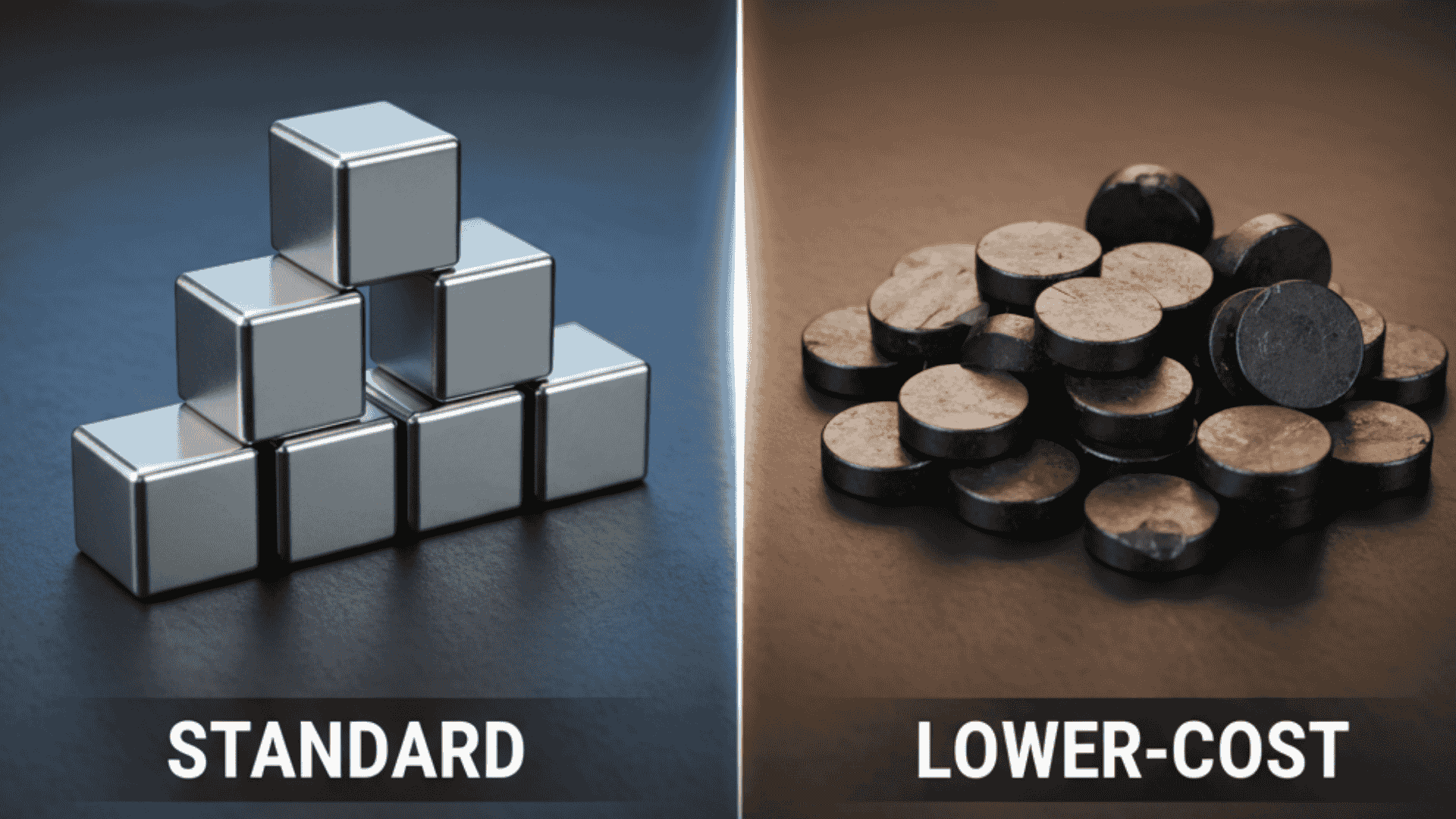

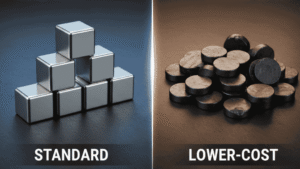

Higher grades, like N52, are more expensive because they require more rare materials and advanced manufacturing. But just because they’re stronger doesn’t mean they’re the best fit for every application. If your product only needs moderate magnetic strength, then paying extra for a higher grade might not make sense.

On the other hand, using too low a grade could mean that your magnet isn’t strong enough, leading to product failures or disappointed customers.

Different industries rely on neodymium magnets for various reasons. Here are a few examples to help you think about your own needs:

By comparing magnet grades carefully, your business can pick a magnet that’s just right—not too weak, not too costly, but precisely what you need.

When selecting rare earth magnet grades, keep these tips in mind:

Understanding N35 to N52 magnet grades can seem tricky at first, but breaking it down into key factors like cost, strength, and application makes the decision much easier.

For businesses, choosing the right neodymium magnet grade is all about balance. Whether you need an affordable N35 for small gadgets or a powerful N52 for industrial use, there’s a magnet grade to match your needs. By understanding magnet grade comparison and the unique features of rare earth magnet grades, you can make smarter decisions that will benefit your bottom line.

The next time you’re thinking about magnets for your product, remember—it’s not just about picking the strongest option. It’s about picking the right option for your application!

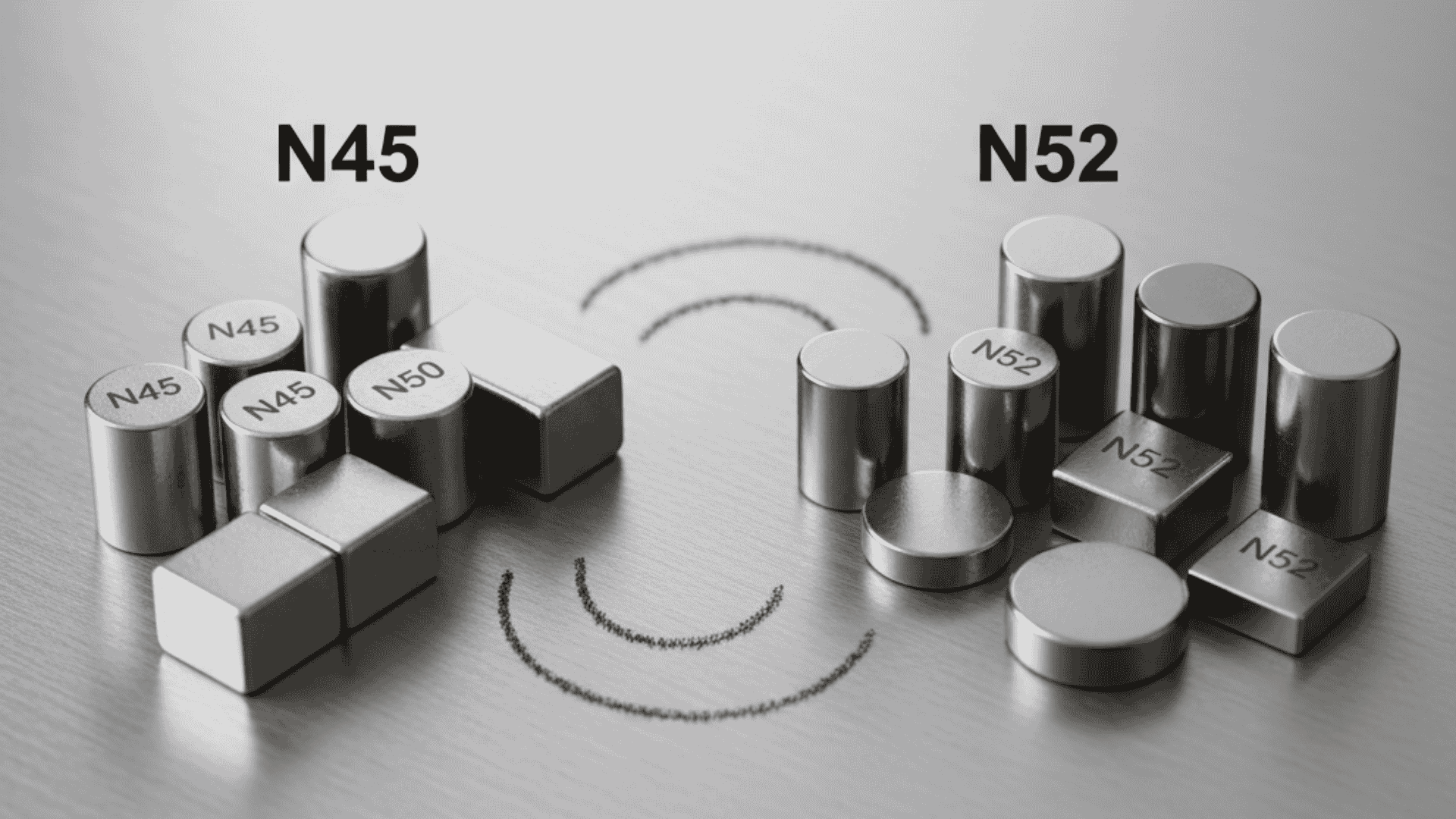

Selecting the right magnet grade is a critical decision for engineers, manufacturers, and product designers. Among the most commonly compared options are N45 and N52

Modern engineering is defined by efficiency, precision, and innovation. As industries push for compact designs, higher performance, and smarter systems, magnetic solutions have become essential

Neodymium magnets have become essential components across industries, from manufacturing and electronics to retail displays and warehouse systems. Known for their exceptional strength and versatility,