When we think of powerful magnets used in high-performance and industrial settings, rare earth magnets like samarium cobalt magnets stand out.

These magnets, also known as SmCo magnets, offer exceptional strength, stability, and durability in challenging environments. Whether you’re designing a medical device, working in aerospace, or developing advanced motors, understanding the advantages of these high-performance magnets can help you make the right choice.

In this blog, we’ll explore what samarium cobalt magnets are, their key features, benefits, and the wide range of samarium cobalt applications in various industries.

Samarium cobalt magnets belong to the rare earth magnet family, which also includes neodymium magnets. While neodymium is more popular due to its superior strength, samarium cobalt has unique properties that make it more suitable for specific environments.

These magnets are made from an alloy of samarium and cobalt. They were developed in the 1970s and were the first commercially available rare earth magnets. There are two main types:

The numbers refer to the atomic ratio of samarium to cobalt in the magnet. Sm2Co17 magnets generally offer better performance and higher resistance to temperature and corrosion.

Samarium-cobalt magnets are known for their strong magnetic force, although they are slightly weaker than neodymium magnets. Still, they are significantly stronger than ceramic or ferrite magnets, making them ideal for industrial magnets used in high-performance applications.

One of the most important advantages of samarium cobalt magnets is their ability to perform at extreme temperatures. These high-temperature magnets can withstand temperatures from -273°C (absolute zero) up to 350°C (662°F) or more, depending on the grade.

This makes SmCo magnets perfect for environments where magnets are exposed to heat, such as motors, turbines, and downhole drilling tools.

Unlike neodymium magnets, which require a protective coating, samarium cobalt magnets are naturally corrosion-resistant. They can be used in humid, salty, or chemically harsh environments without losing their magnetic power. This makes them ideal for applications in the marine or chemical industries.

Samarium cobalt magnets have a high coercivity, meaning they resist becoming demagnetized when exposed to external magnetic fields or high temperatures. This property makes them reliable in situations where stable magnetic performance is critical.

SmCo magnets are mechanically brittle, so they can chip or crack if dropped or handled roughly. However, once installed in a device, they are very durable and maintain their magnetic properties over time, even in tough operating conditions.

Thanks to their thermal stability and corrosion resistance, samarium cobalt magnets are the best choice for demanding applications. They can operate efficiently in:

This makes them a preferred option over other magnets in challenging settings.

Because they are less likely to corrode or lose their magnetism, SmCo magnets offer long-term reliability. Their strong resistance to demagnetization means they won’t require frequent replacements or maintenance, which reduces downtime and costs.

Since SmCo magnets are powerful, they allow designers to use smaller-sized magnets without compromising performance. This is especially important in industries like electronics, automotive, and aerospace, where space and weight are at a premium.

SmCo magnets are used in many types of electric motors and generators. Their stable performance improves energy efficiency, reduces wear, and supports longer equipment life.

Because of their stability, these magnets are ideal for sensitive instruments like:

In these critical areas, magnetic performance can’t afford to fluctuate, and samarium cobalt magnets deliver consistent results.

Samarium cobalt applications are vast and varied. These magnets are used in industries ranging from healthcare to renewable energy. Their versatility comes from their ability to meet the demands of different environments and technical requirements, making them a go-to solution for engineers and designers.

Thanks to their corrosion resistance and durability, samarium cobalt magnets require less maintenance than other types of magnets. This reduces downtime and replacement costs, making them an economical choice for long-term use in industrial settings.

In aircraft and spacecraft, every component must withstand extreme conditions. SmCo magnets are used in:

Their high-temperature tolerance and stability under pressure make them ideal for aerospace technologies.

The medical industry relies on SmCo magnets for equipment like MRI machines, where strong and stable magnetic fields are essential. Their corrosion resistance also makes them suitable for implantable devices, such as pacemakers, where biocompatibility and durability are crucial.

Samarium cobalt’s consistency and resistance to interference make it an excellent choice.

Electric and hybrid vehicles require durable, heat-resistant magnets for motors and control systems. SmCo magnets support long-term, efficient performance in these high-demand environments.

In manufacturing and processing equipment, industrial magnets must perform under intense pressure, heat, and vibration. Samarium cobalt is widely used in magnetic couplings, pumps, and sensors in harsh industrial settings.

Downhole tools used in drilling operations must endure extreme temperatures and pressure. SmCo magnets function reliably in such extreme environments, making them a top choice for energy companies.

While both neodymium and samarium cobalt magnets belong to the rare earth family, each has unique strengths.

| Feature | Neodymium | Samarium Cobalt |

| Magnetic Strength | Higher | Slightly lower |

| Temperature Resistance | Up to 150°C | Up to 350°C |

| Corrosion Resistance | Requires coating | Naturally resistant |

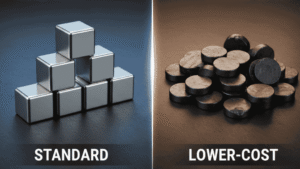

| Cost | Less expensive | More expensive |

| Demagnetization Resistance | Moderate | High |

So, if your project demands the strongest possible magnetic force, neodymium may be better. But if you need a magnet that works in hot, wet, or chemically aggressive environments, samarium cobalt is the clear winner.

When selecting a magnet, it’s important to consider the conditions it will face. SmCo magnets may cost more than other options, but their performance, durability, and reliability often justify the investment, especially for applications where failure is not an option.

Whether you’re working in aerospace, medical, automotive, or manufacturing, samarium cobalt magnets can be the solution you’re looking for when standard magnets fall short.

Samarium cobalt magnets, or SmCo magnets, are a powerhouse in the world of rare earth magnets. Their exceptional strength, high-temperature resistance, and durability make them a top choice for industries ranging from aerospace to healthcare.

With applications in electric vehicles, renewable energy, and consumer electronics, these industrial magnets are driving innovation and efficiency across the globe. While they may come with a higher price tag and some handling challenges, the benefits of samarium cobalt magnets—reliability, versatility, and energy efficiency—make them a valuable investment.

As technology continues to evolve, SmCo magnets will remain a critical component in shaping the future of high-performance applications.

If your project demands precision, power, and resilience, samarium cobalt could be the ideal material for the job.

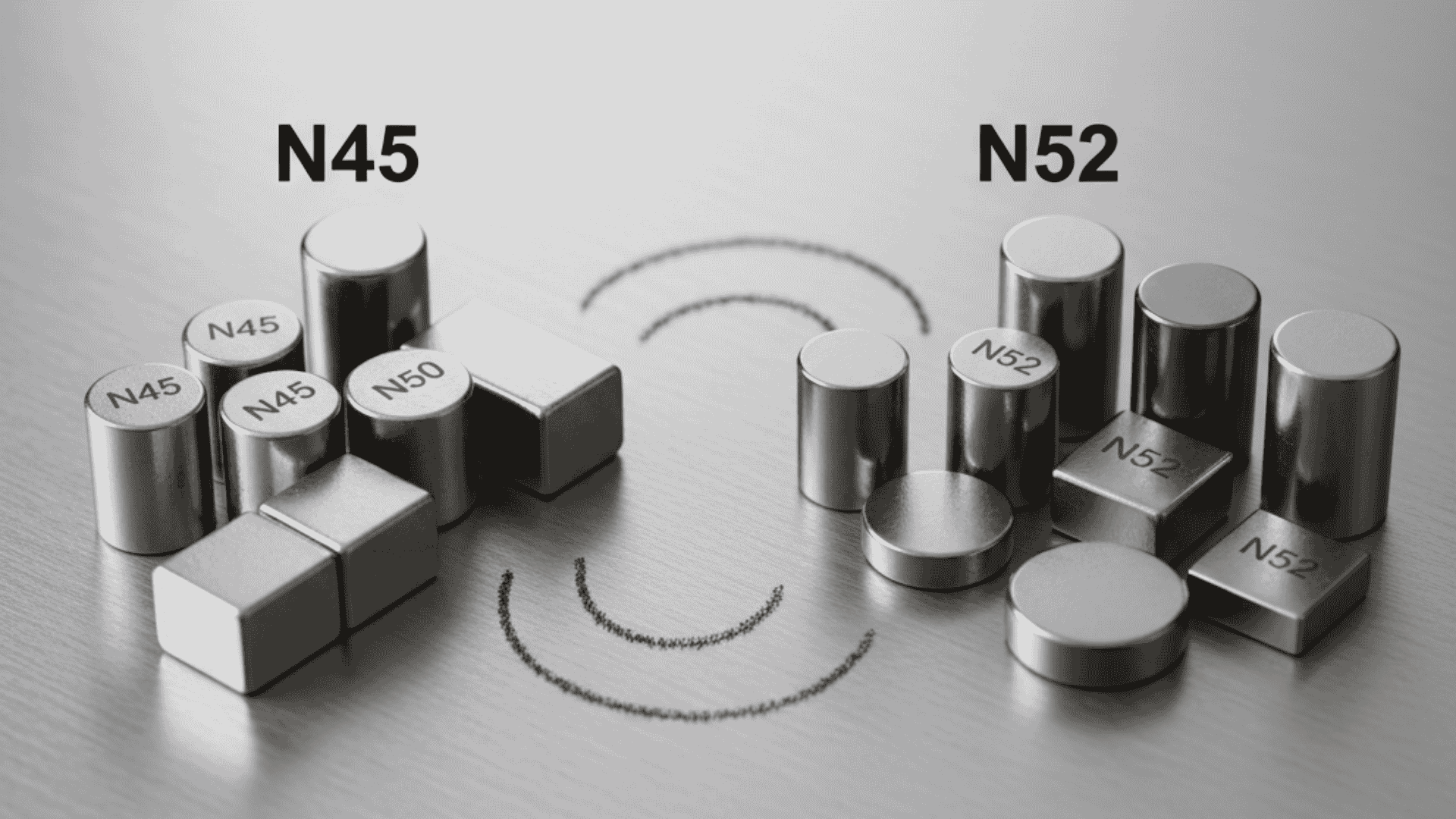

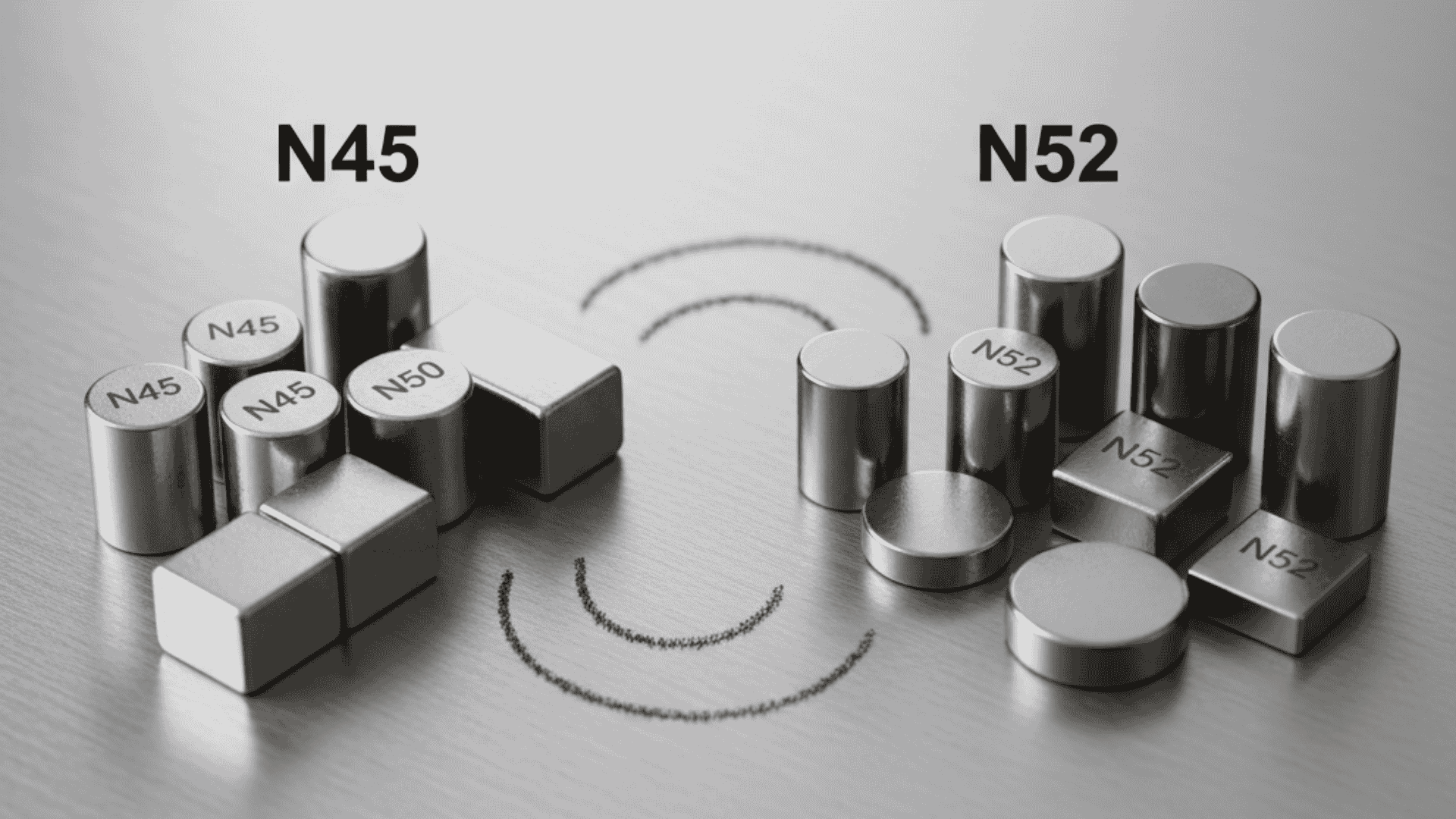

Selecting the right magnet grade is a critical decision for engineers, manufacturers, and product designers. Among the most commonly compared options are N45 and N52

Modern engineering is defined by efficiency, precision, and innovation. As industries push for compact designs, higher performance, and smarter systems, magnetic solutions have become essential

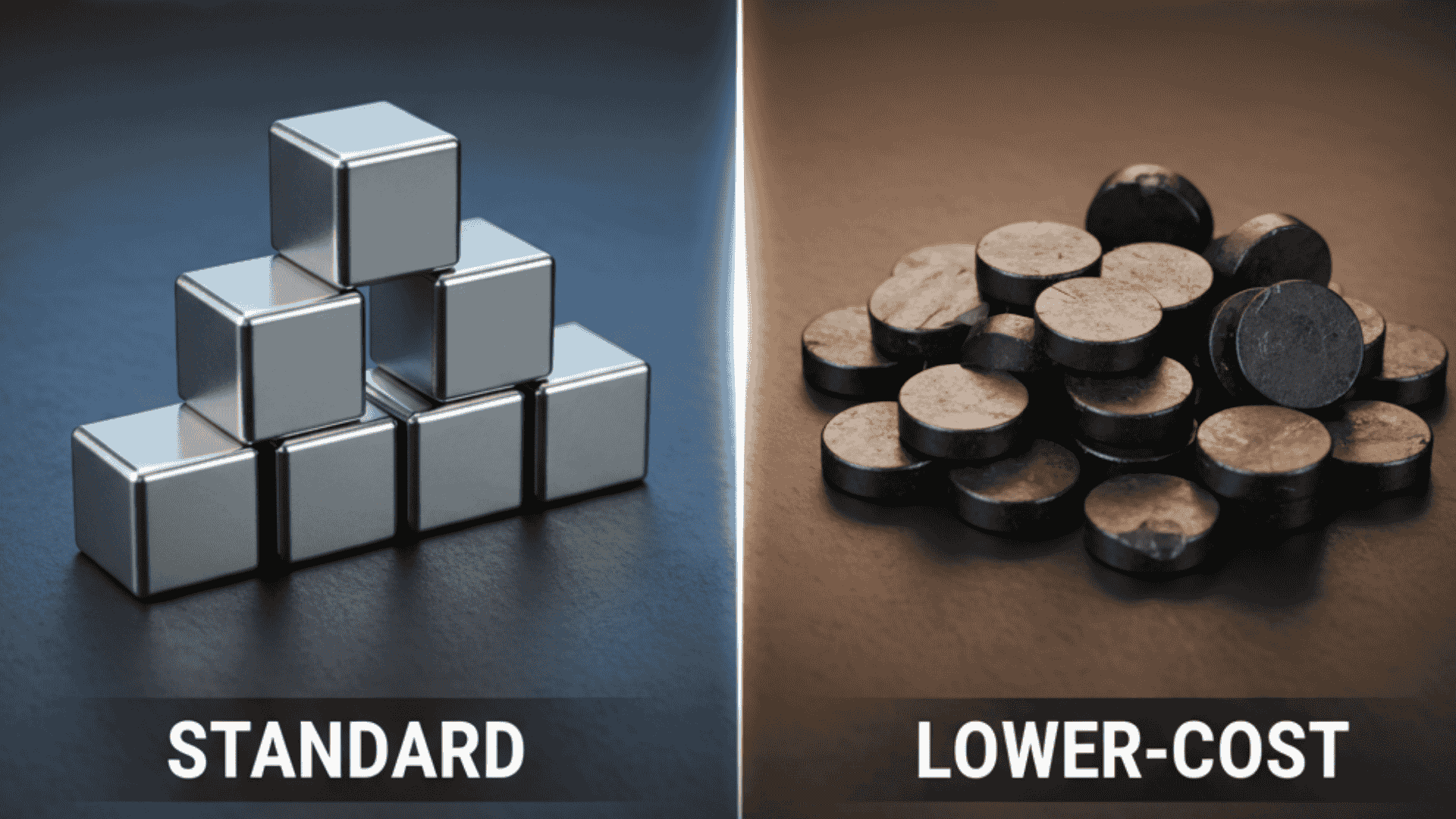

Neodymium magnets have become essential components across industries, from manufacturing and electronics to retail displays and warehouse systems. Known for their exceptional strength and versatility,