Warehouse and industrial environments depend on clear, durable rack labels to maintain seamless organization, accurate inventory tracking, and smooth daily operations. However, as warehouse layouts evolve, barcodes become obsolete, or labels fade and deteriorate, proper removal becomes just as important as proper labeling. Knowing how to remove rack labels correctly helps prevent stubborn adhesive residue, protects rack surfaces from damage, and ensures ongoing safety compliance, keeping your facility efficient, professional, and ready for change. This guide walks you through a safe, effective, and professional approach to rack label removal while protecting your racking system and maintaining warehouse efficiency.

Rack labels are typically designed to be durable, resistant to dust, moisture, and wear. While this durability is beneficial during use, it makes rack label removal more challenging. Removing labels incorrectly can scratch metal racks, weaken protective coatings, or leave sticky residue that attracts dirt and dust.

A careful and systematic approach ensures:

Whether you manage a distribution center, manufacturing facility, or storage warehouse, safe label removal is a critical maintenance task. Boost your warehouse productivity by implementing a well-structured rack labelling strategy. This article explores how an effective rack labelling system enhances accuracy, reduces errors, and streamlines inventory management.

Before starting the process, gather the right tools. Preparation reduces time, effort, and the risk of damage.

Common tools include:

Using proper tools is especially important when performing warehouse rack label removal on large-scale racking systems.

Start by examining the label type and the rack material. Most racks are metal with protective coatings, so understanding the surface helps determine the safest removal method. This initial assessment is key to planning adhesive rack label removal without surface damage.

Heat softens adhesive, making labels easier to peel. Use a hair dryer or low-heat gun and apply warmth evenly across the label for 20–30 seconds.

This step is crucial when you want to remove rack label safely, especially in cold warehouse environments where adhesives harden over time.

Once heated, gently lift one corner using a plastic scraper. Peel the label back slowly at a low angle. Rushing this step increases the chance of tearing the label or leaving adhesive behind.

This technique works particularly well when you need to remove labels from metal racks without damaging paint or protective finishes.

Even after peeling, residue may remain. Apply a small amount of adhesive remover or alcohol to a cloth and gently rub the area. Avoid harsh chemicals that could corrode metal or strip coatings.

This is a key part of effective industrial label removal, especially in high-use facilities where adhesives are designed to be long-lasting.

After residue removal, clean the rack with a mild solution and dry thoroughly. This ensures the surface is ready for relabeling or inspection.

Proper cleaning is essential for smooth shelving label removal and helps new labels adhere securely without peeling.

Once labels are removed, inspect racks for scratches, rust, or coating damage. Addressing these issues promptly helps maintain rack integrity and warehouse safety standards.

This final check is an often-overlooked but important part of professional rack label removal practices. Optimize your storage operations with expert insights from our comprehensive guide on warehouse racking labels. Discover the best way to label warehouse racking and enhance accuracy, efficiency, and safety in your facility.

Many facilities unknowingly damage racks during label removal. Avoid these common errors:

These mistakes can complicate future warehouse rack label removal efforts and lead to costly repairs or compliance issues.

While small-scale removal may be manageable, large warehouses or distribution centers often require professional support. High-volume racks, aged labels, or specialized adhesives demand expertise, proper tools, and efficient processes.

Professional services specialize in industrial label removal, ensuring consistency, speed, and minimal disruption to operations. They also ensure labels are removed evenly across entire facilities, maintaining a clean and professional appearance.

Benefits of Professional Rack Label Removal

Hiring experts for adhesive rack label removal offers several advantages:

Professional teams understand how to handle complex shelving label removal projects safely and efficiently.

Rack labeling is often tied to warehouse safety regulations. Improper removal can create confusion, misidentification, or compliance gaps. Ensuring accurate removal and replacement supports operational safety and inventory accuracy.

A systematic approach to remove rack labels safely also reduces workplace hazards caused by loose labels, sticky residue, or damaged rack surfaces.

Knowing how to remove rack labels correctly protects your warehouse infrastructure, improves efficiency, and ensures a clean, organized environment. While small projects can be handled in-house, large-scale or complex warehouse rack label removal is best left to professionals.

If you’re looking for reliable, efficient, and damage-free rack label services, Rochester Magnet is the right choice. With industry expertise and proven solutions, we ensure safe, precise, and professional rack label removal tailored to your facility’s needs.

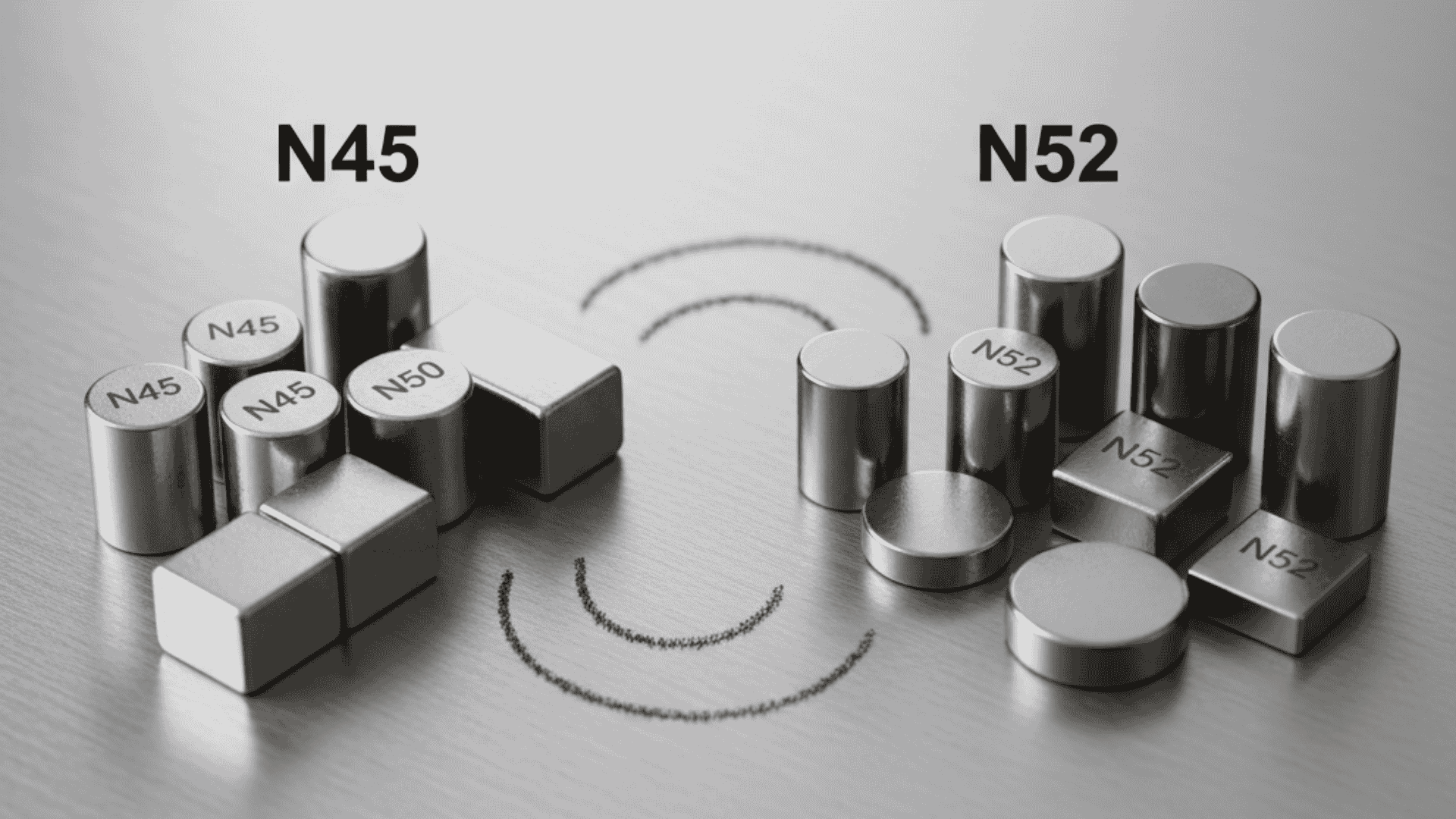

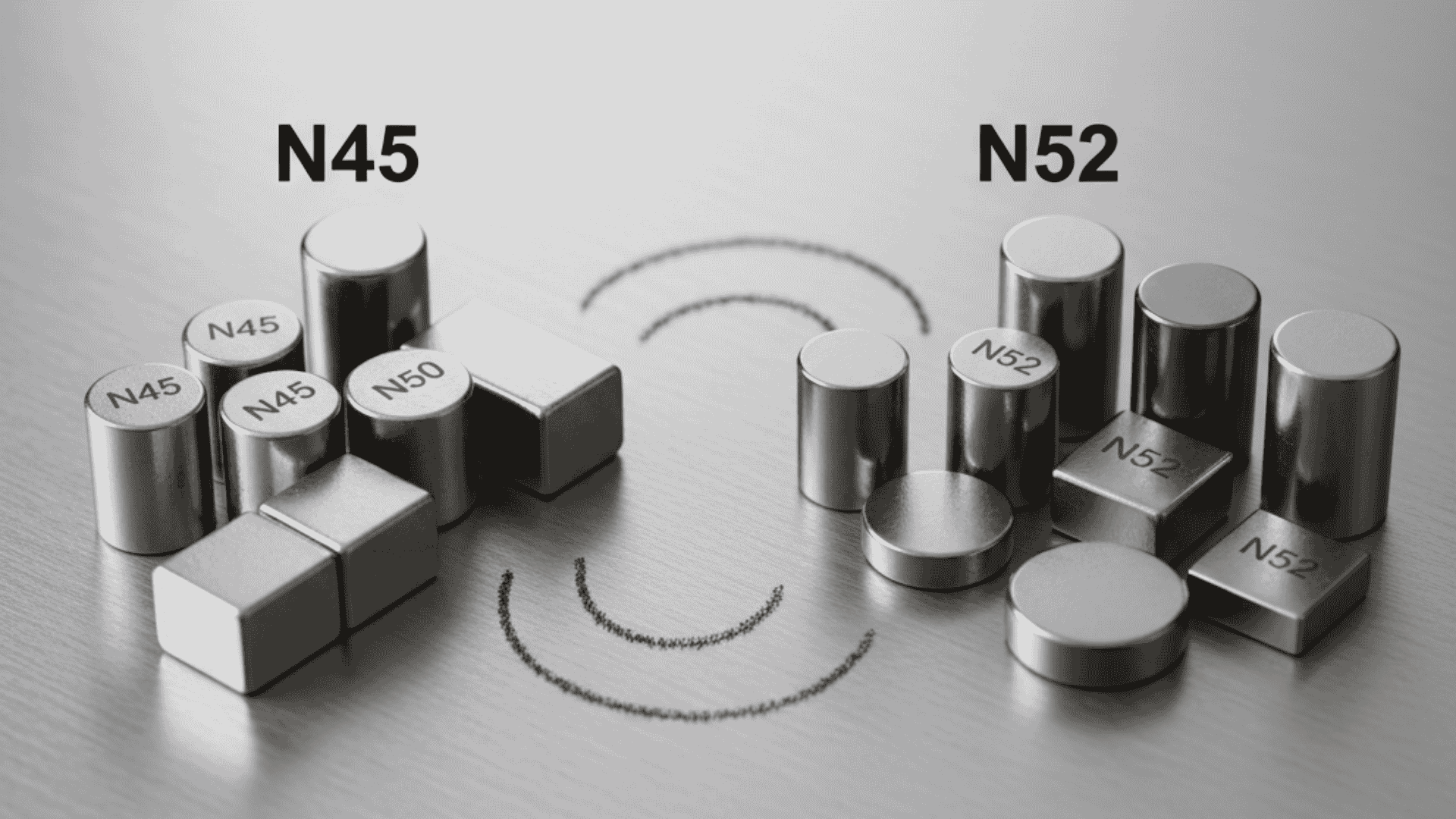

Selecting the right magnet grade is a critical decision for engineers, manufacturers, and product designers. Among the most commonly compared options are N45 and N52

Modern engineering is defined by efficiency, precision, and innovation. As industries push for compact designs, higher performance, and smarter systems, magnetic solutions have become essential

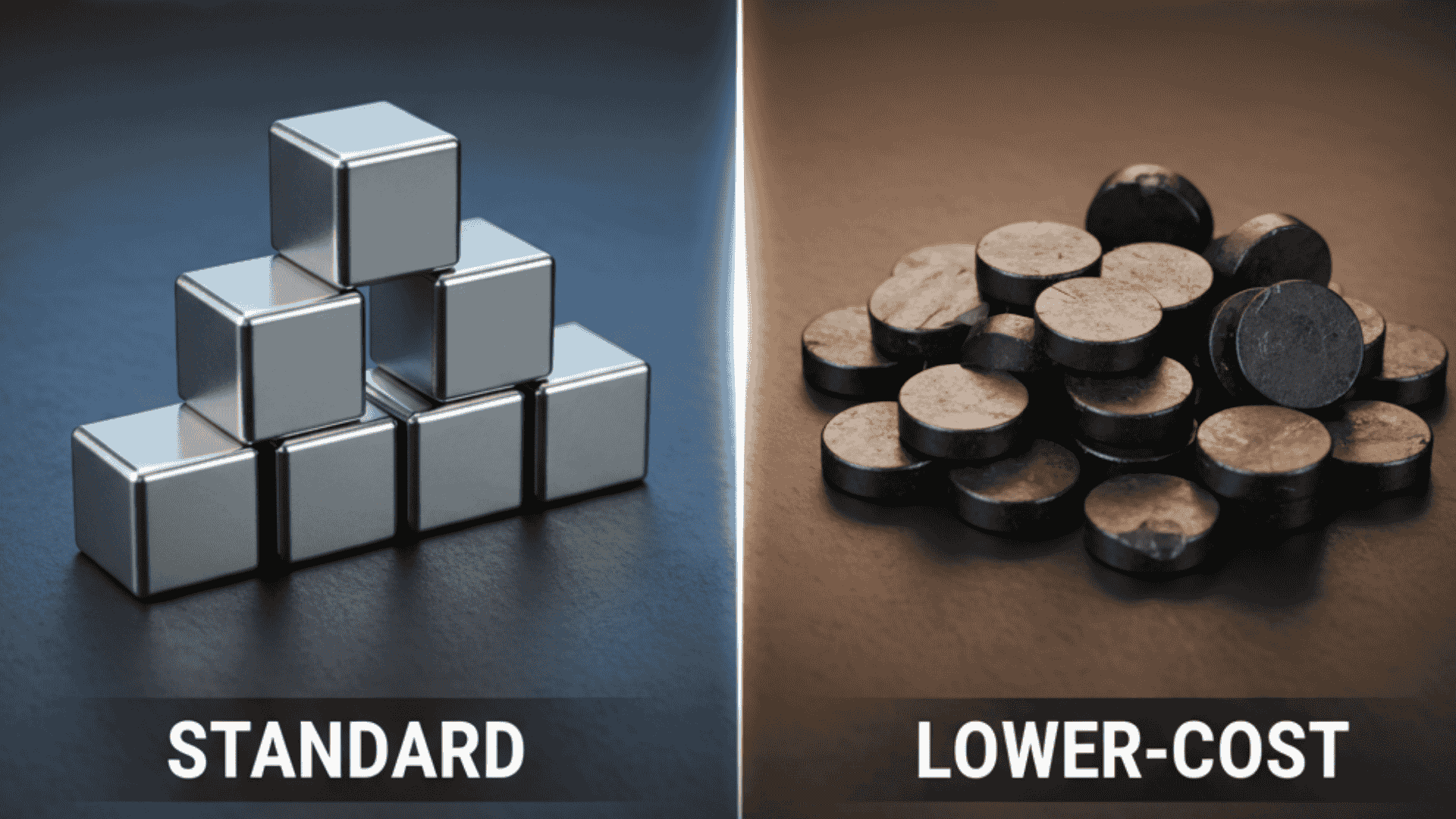

Neodymium magnets have become essential components across industries, from manufacturing and electronics to retail displays and warehouse systems. Known for their exceptional strength and versatility,