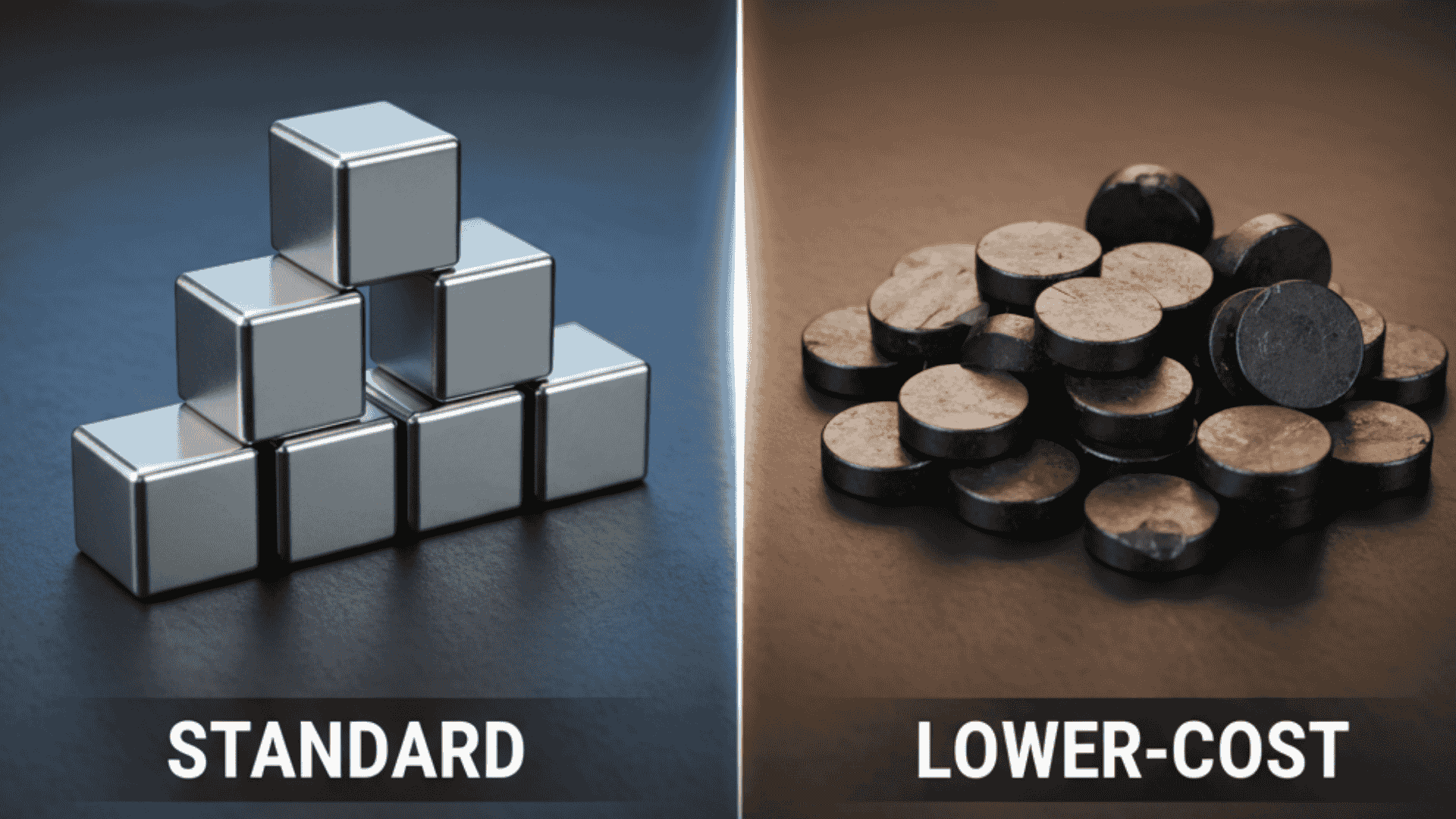

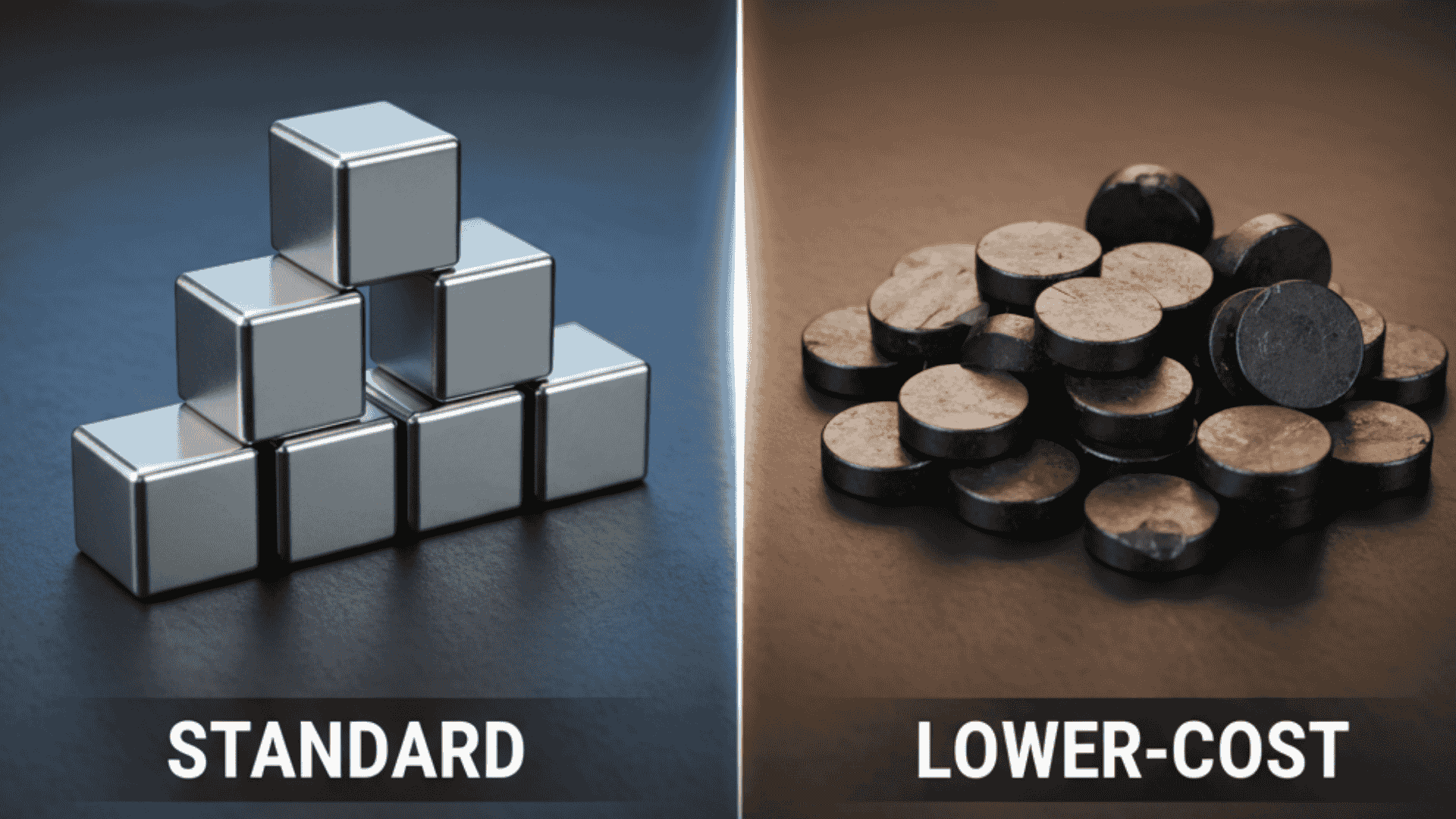

Neodymium magnets have become essential components across industries, from manufacturing and electronics to retail displays and warehouse systems. Known for their exceptional strength and versatility, these rare-earth magnets offer unmatched performance in compact form. However, not all neodymium magnets are created equal, and understanding the differences between standard neodymium magnets and lower cost neodymium magnets is crucial for selecting the right option for your application. In this comprehensive guide, we’ll break down key factors to consider in a neodymium magnet comparison, explore how neodymium magnet grades influence performance, and explain when it’s worth investing in premium magnets versus more affordable neodymium magnet options.

Neodymium magnets are a type of rare-earth magnet composed of an alloy of neodymium, iron, and boron (NdFeB). They are widely recognized as the strongest commercially available permanent magnets, offering significantly higher magnetic field strength than ceramic or alnico magnets of similar size. This strength makes them ideal for applications requiring powerful magnetic pull in compact physical dimensions.

When comparing different neodymium magnet options, it’s important to understand that performance, durability, and cost are all influenced by material composition, manufacturing process, surface coating, and quality control.

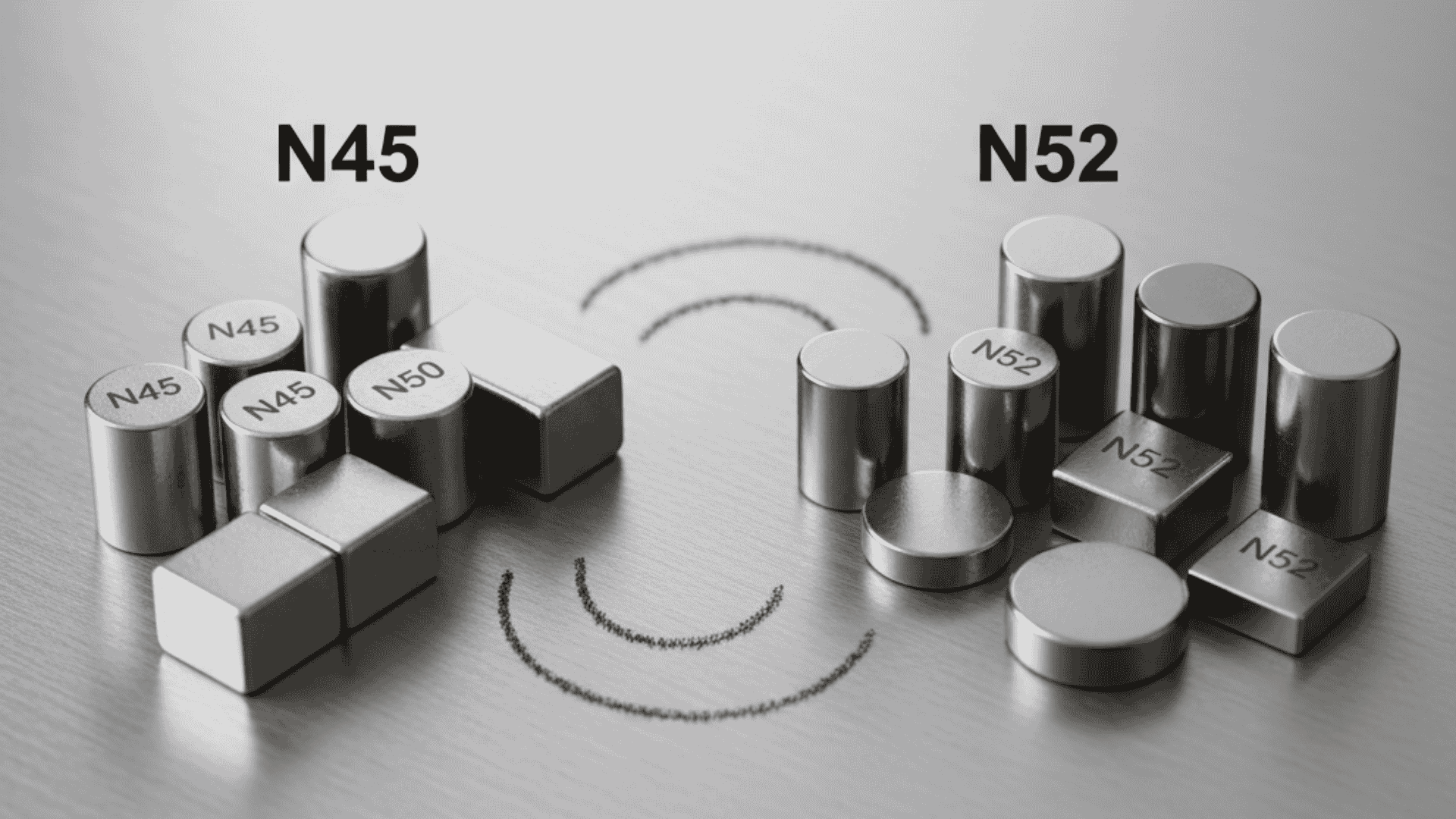

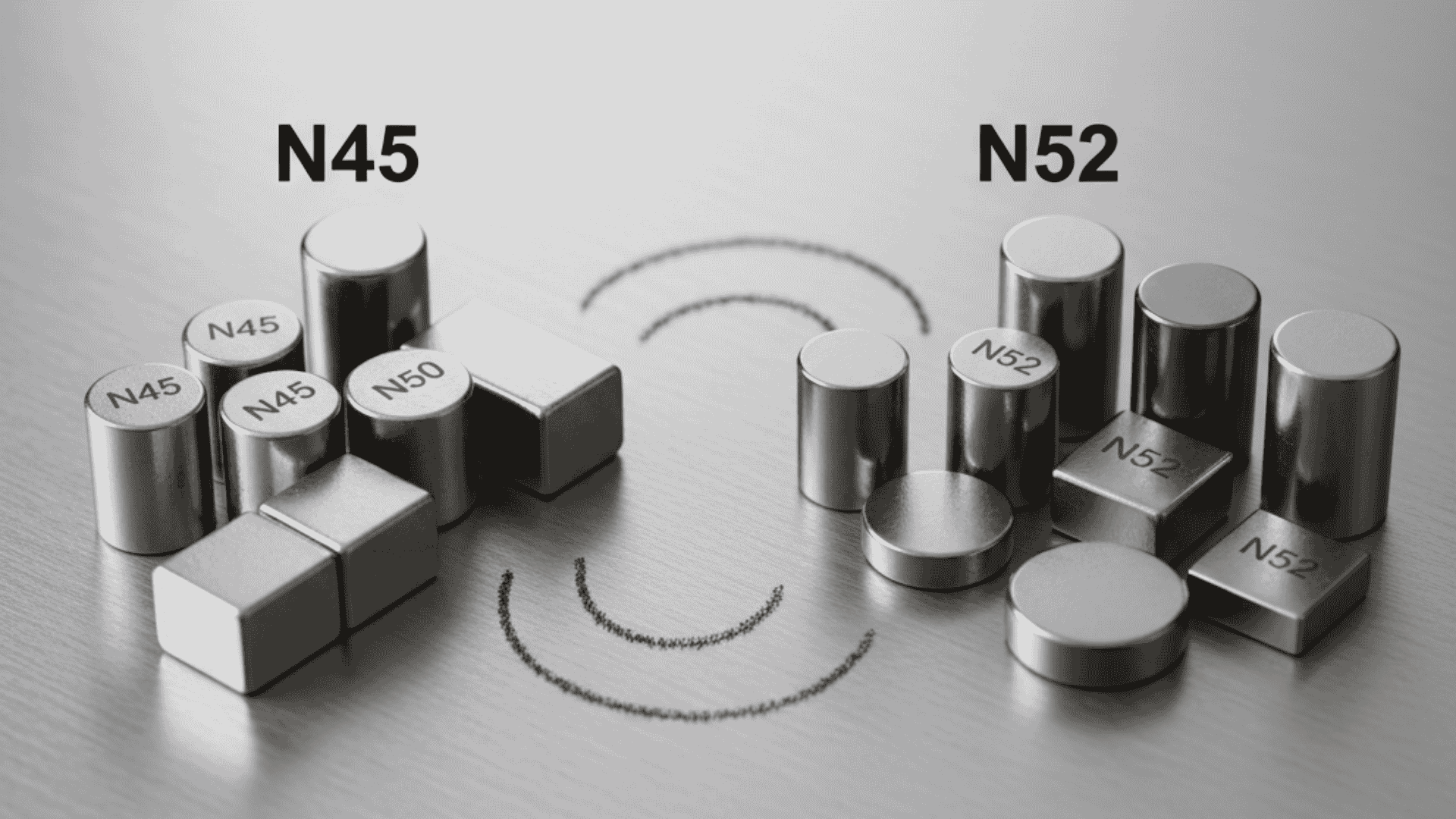

A key component in any neodymium magnet comparison is the magnet grade. Grades indicate the maximum energy product (measured in Mega-Gauss Oersteds, or MGOe) and directly reflect the magnet’s strength. Common grades include N35, N42, N52, and others. Higher grade magnets (e.g., N52) deliver stronger magnetic force but are typically more expensive.

Standard neodymium magnets usually fall within established grade ranges that balance strength, reliability, and cost. Lower cost neodymium magnets may use lower grade material or looser manufacturing tolerances to reduce production costs and final price. Explore our in-depth guide on neodymium magnet grades and learn how different material compositions impact magnetic strength, performance, and application suitability.

Standard neodymium magnets are manufactured to specific grade standards, ensuring consistent performance. Whether the application requires strong holding force, precise alignment, or reliable retention, these magnets deliver predictable results. In a magnet strength comparison, standard options typically outperform lower cost alternatives, particularly in demanding environments.

High-quality neodymium magnets come with robust protective coatings such as nickel-copper-nickel (Ni-Cu-Ni), epoxy, or other finishes that resist corrosion and wear. This is especially important for magnets exposed to humidity, temperature fluctuations, or repeated physical contact. Investing in quality coatings can prevent premature failure, something to consider when choosing between standard and cheaper options.

Standard magnets undergo thorough testing and stricter quality control processes, resulting in tighter tolerances and greater performance predictability. This reliability is critical in precision applications such as sensor systems, medical devices, robotics, and automated machinery where even minor variations can cause failures. Discover the power and versatility of neodymium magnets at Rochester Magnet, engineered for maximum strength, reliability, and performance across industrial, commercial, and everyday applications.

The primary advantage of lower cost neodymium magnets is savings. These options appeal to projects with tight budgets or where performance demands are modest. For example, in educational kits, DIY projects, or low-stress holding tasks, affordable magnets may provide sufficient strength without a significant financial commitment.

Lower cost magnets often use reduced material content, lower grades, or simplified finishing processes. As a result, a magnet strength comparison will typically show that these magnets have lower pull forces and may not maintain performance over time under heavy load or environmental stress.

Affordable neodymium magnet options are practical for applications where:

In these scenarios, a lower cost magnet may satisfy functional needs without unnecessary expense. Learn everything you need to know about neodymium magnets with this comprehensive guide from RS Online. It covers essential topics like magnet properties, applications, safety considerations, and performance factors to help you choose the right magnetic solution.

When evaluating magnet strength in a neodymium magnet comparison, it’s important to consider both pull force and magnetic field stability. Standard magnets consistently demonstrate stronger pull forces due to higher grades and precise manufacturing. Lower cost magnets often show variability in strength, which can be acceptable for casual or non-critical uses, but inappropriate for safety-sensitive applications.

For instance, standard neodymium magnets may retain strength at higher temperatures or under varying load conditions, whereas lower cost options can demagnetize more easily when subjected to heat or physical stress.

The value of a magnet becomes clear when applied to specific tasks:

In environments such as conveyor systems, assembly operations, or magnetic fixturing, reliability and strength are non-negotiable. Standard neodymium magnets offer the durability and consistent performance required for industrial workloads. Choosing lower cost magnets in these settings could lead to operational failures, increased downtime, and higher long-term costs.

Precision devices such as sensors, actuators, and magnetic couplings demand uniform magnetic fields and tight tolerances. Standard magnets ensure that engineered specifications are met. In contrast, lower cost neodymium magnets may introduce variability that compromises product performance.

For lighter use, such as refrigerator magnets, bulletin board systems, or simple holding tasks, affordable neodymium magnet options can be perfectly sufficient. In these cases, the lower cost and reasonable performance balance is advantageous.

Selecting between standard and lower cost neodymium magnets requires aligning performance expectations with application demands and budget constraints.

The answers guide decisions toward either premium standard options or more economical alternatives.

While it may seem appealing to opt for the cheapest magnet available, evaluating neodymium magnet grades and comparing performance ensures that cost savings don’t compromise functionality. Often, the real value lies in investing slightly more for standard magnets that deliver longevity, reliability, and consistent results, especially in professional or heavy-duty applications.

Investing in quality also minimizes replacement needs and performance risks. This is particularly relevant for commercial users, engineers, designers, and facility planners who depend on magnetic components as part of larger systems.

A clear neodymium magnet comparison reveals that standard neodymium magnets and lower cost neodymium magnets each have their place depending on application requirements and budget limitations. Standard options generally provide superior strength, consistency, and durability, making them ideal for industrial use, precision engineering, and high-performance settings. Lower cost magnets, while suitable for less demanding tasks, often fall short in strength and longevity when compared directly with higher-grade counterparts.

When evaluating your needs, consider both magnet strength comparison and neodymium magnet grades to ensure you select the right solution. Whether your project calls for robust magnetic performance or cost-effective holding power, making an informed choice prevents future setbacks.

For professional guidance and high-quality magnet solutions tailored to your specific needs, choose Rochester Magnet, the reliable partner for all your magnetic component and industrial magnet requirements.

Selecting the right magnet grade is a critical decision for engineers, manufacturers, and product designers. Among the most commonly compared options are N45 and N52

Modern engineering is defined by efficiency, precision, and innovation. As industries push for compact designs, higher performance, and smarter systems, magnetic solutions have become essential

Neodymium magnets have become essential components across industries, from manufacturing and electronics to retail displays and warehouse systems. Known for their exceptional strength and versatility,