Modern engineering is defined by efficiency, precision, and innovation. As industries push for compact designs, higher performance, and smarter systems, magnetic solutions have become essential components across a wide range of applications. Among these, custom neodymium magnets stand out as one of the most powerful and versatile tools available to engineers today. Known for their exceptional strength-to-size ratio and adaptability, these magnets are shaping how products are designed, manufactured, and optimized.

From advanced automation systems to renewable energy technologies, neodymium-based solutions are enabling engineers to solve complex challenges while maintaining reliability and cost efficiency.

Neodymium magnets belong to the family of rare earth magnets and are widely recognized as the strongest permanent magnets commercially available. Their strength allows engineers to achieve higher performance with smaller components, which is critical in modern product design where space and weight constraints are common.

In engineering applications, neodymium magnets are valued not only for their magnetic force but also for their consistency, durability, and ability to be tailored to specific operational needs. When designed to exact specifications, these magnets integrate seamlessly into mechanical, electrical, and electronic systems. Comprehensive overview of neodymium magnets’ properties, manufacturing, grades, performance characteristics, and diverse engineering applications across industries. Comprehensive overview of neodymium magnets’ properties, manufacturing, grades, performance characteristics, and diverse engineering applications across industries.

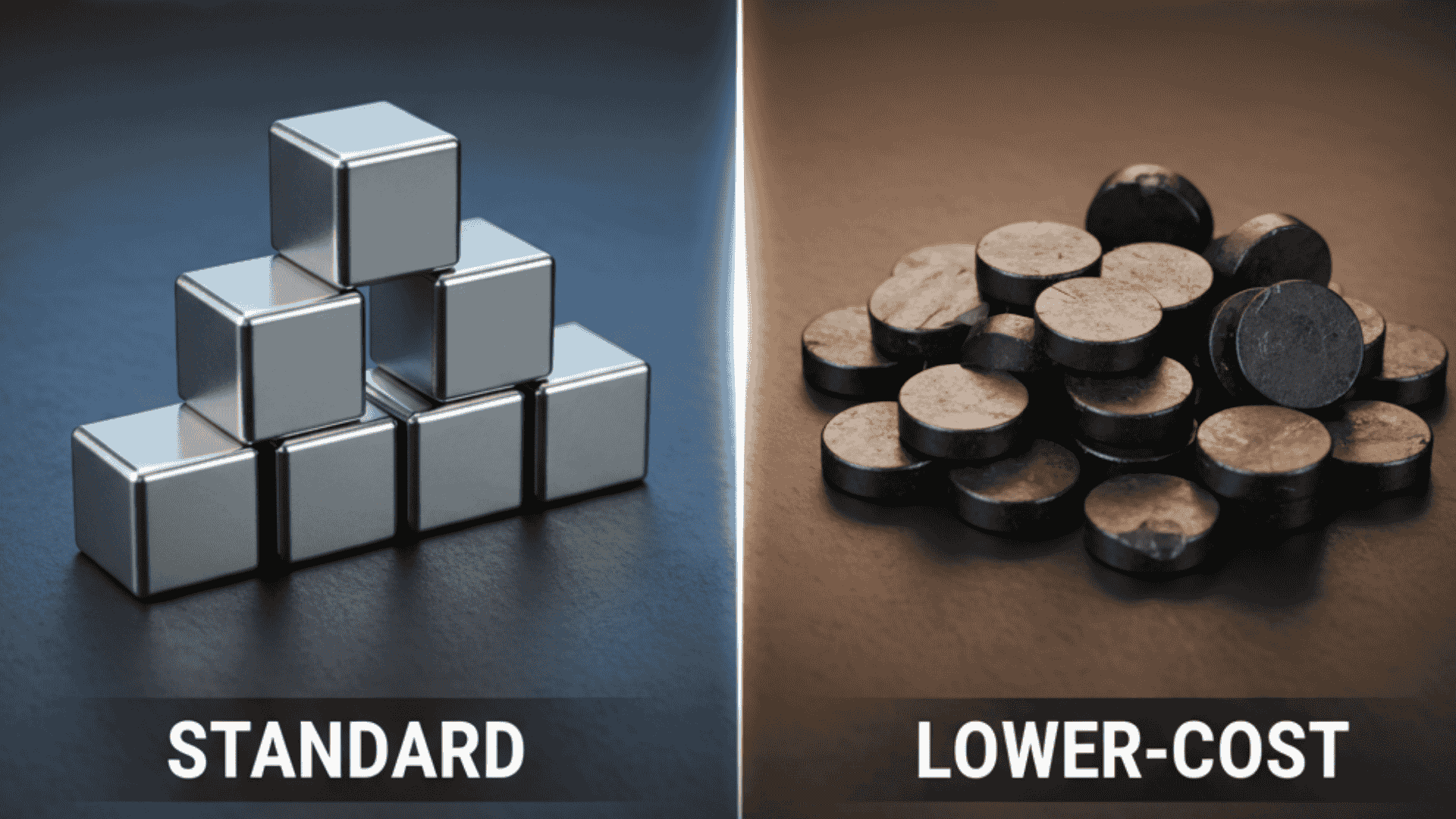

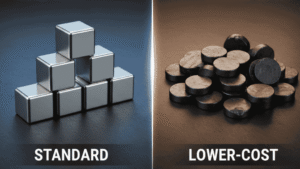

One of the biggest advantages of using customized magnetic solutions is flexibility. Engineers often face unique requirements related to shape, size, magnetic orientation, coating, or temperature resistance. Custom rare earth magnets allow manufacturers to fine-tune these characteristics to match demanding design parameters.

Customization supports:

By aligning magnet design with application requirements, engineering teams can achieve better results than with off-the-shelf components.

Automation systems rely heavily on precision and repeatability. In modern manufacturing environments, industrial neodymium magnets are widely used in robotic arms, conveyors, sensors, and holding systems. Their high magnetic strength enables secure gripping, accurate positioning, and fast response times.

These magnets play a critical role in:

Because they retain strong magnetic properties over time, neodymium magnets help ensure reliability in high-cycle industrial operations.

The automotive industry is undergoing rapid transformation, driven by electrification, automation, and lightweight design. Neodymium magnets in engineering applications are essential in electric motors, sensors, actuators, and power steering systems.

In electric and hybrid vehicles, neodymium magnets enable:

Their use contributes directly to better vehicle performance, reduced energy consumption, and lower emissions, aligning with global sustainability goals.

Renewable energy technologies demand components that can deliver high performance under variable and often harsh conditions. High strength neodymium magnets are widely used in wind turbines and energy generation systems where consistent magnetic force is critical.

In wind power applications, these magnets:

By eliminating the need for gearboxes in many systems, neodymium magnets help reduce maintenance requirements and extend operational lifespan.

Precision and reliability are non-negotiable in medical engineering. Magnetic components are used in imaging systems, diagnostic devices, and laboratory equipment where accuracy and stability are paramount. Neodymium magnet applications in this sector support compact designs without compromising performance.

Common uses include:

Their ability to deliver consistent magnetic fields in small form factors makes them ideal for advanced healthcare technologies.

Modern electronics continue to shrink in size while increasing in capability. From smartphones to wearable devices, magnetic components must deliver high performance within limited space. Custom-designed neodymium magnets are widely used in speakers, microphones, vibration motors, and haptic feedback systems.

Their strength enables:

As consumer expectations grow, engineers rely on magnetic solutions that support innovation without compromising durability.

Aerospace and defense engineering demands materials that perform reliably under extreme conditions, including high temperatures, vibration, and pressure. Neodymium magnets are used in actuators, control systems, navigation equipment, and sensing devices where precision is critical.

Custom magnet solutions allow engineers to:

These benefits make neodymium magnets indispensable in advanced aerospace designs.

Magnetic solutions are also essential in lifting, separation, and safety systems across various industries. Custom neodymium magnets are used in magnetic lifters, holding fixtures, and safety interlocks where strong and reliable holding force is required.

These systems improve:

By tailoring magnetic strength and geometry, engineers can design systems that meet exact load and safety requirements.

As technology continues to evolve, the role of neodymium magnets will expand further. Advances in coating technologies, thermal resistance, and magnetic modeling are opening new possibilities for engineers. Increased focus on sustainability is also driving innovation in material usage and recycling processes.

Emerging trends include:

These developments ensure that neodymium magnets will remain a cornerstone of modern engineering for years to come. Insightful blog exploring key uses of neodymium ring magnets, highlighting performance, engineering benefits, and versatile applications across modern industrial and technological sectors.

The versatility and performance of neodymium magnets have made them essential across nearly every engineering discipline. From automation and renewable energy to healthcare and consumer electronics, their impact is both broad and transformative. By leveraging customized designs, engineers can unlock higher efficiency, precision, and innovation in their products.

As engineering challenges grow more complex, the demand for powerful, adaptable magnetic solutions will only increase. Neodymium magnets, when thoughtfully designed and applied, continue to enable progress at the intersection of performance and possibility. Premium supplier of custom neodymium magnets and rare earth solutions, delivering industrial strength, precision design, engineering support, and tailored magnetic products for diverse applications. Get in touch with expert magnet specialists for custom solutions, technical guidance, quotes, and responsive customer support to fulfill all magnetic product requirements.

Modern engineering is defined by efficiency, precision, and innovation. As industries push for compact designs, higher performance, and smarter systems, magnetic solutions have become essential

Neodymium magnets have become essential components across industries, from manufacturing and electronics to retail displays and warehouse systems. Known for their exceptional strength and versatility,

Warehouse and industrial environments depend on clear, durable rack labels to maintain seamless organization, accurate inventory tracking, and smooth daily operations. However, as warehouse layouts

Our magnet experts will help you get exactly what you need – custom or stock – in record time with great quality at a very competitive price.

Ⓒ 2025 - All Rights Are Reserved